Many types of spanners/wrenches are used, each being suited for a specific purpose. The name of a spanner/wrench is derived from either its shape, its use, or its construction.

or

What are spanners/wrenches?

When you connect two or more parts, then use nuts and bolts. The tools, which are used to open or tight the nuts and bolts are called spanners. Spanners are also called wrenches and in generally called chabi or Panna. After fitting the mouth of spanners with nuts and bolts, apply adequate force on the handle to operate these as required.

Spanners are made up of steel by forging and then hard and tempered. It is available in different shapes and sizes. So, there are many kinds of spanners and wrenches.

Types of Spanners/Wrenches

There are many types of spanners/wrenches given below

1. Open-Ended Spanner

It is a hand tool made of high carbon steel with a handle, carrying jaws or holes of a particular shape i.e. designed to grip a nut/bolt head. It has an open curved on both sides i.e., a hook at one end for engaging notches or holes in certain kinds of nuts/bolts.

Advantages:

- Easy to use and versatile

- Can be used in tight spaces

Disadvantages:

- Less grip on the nut or bolt

- More likely to slip off

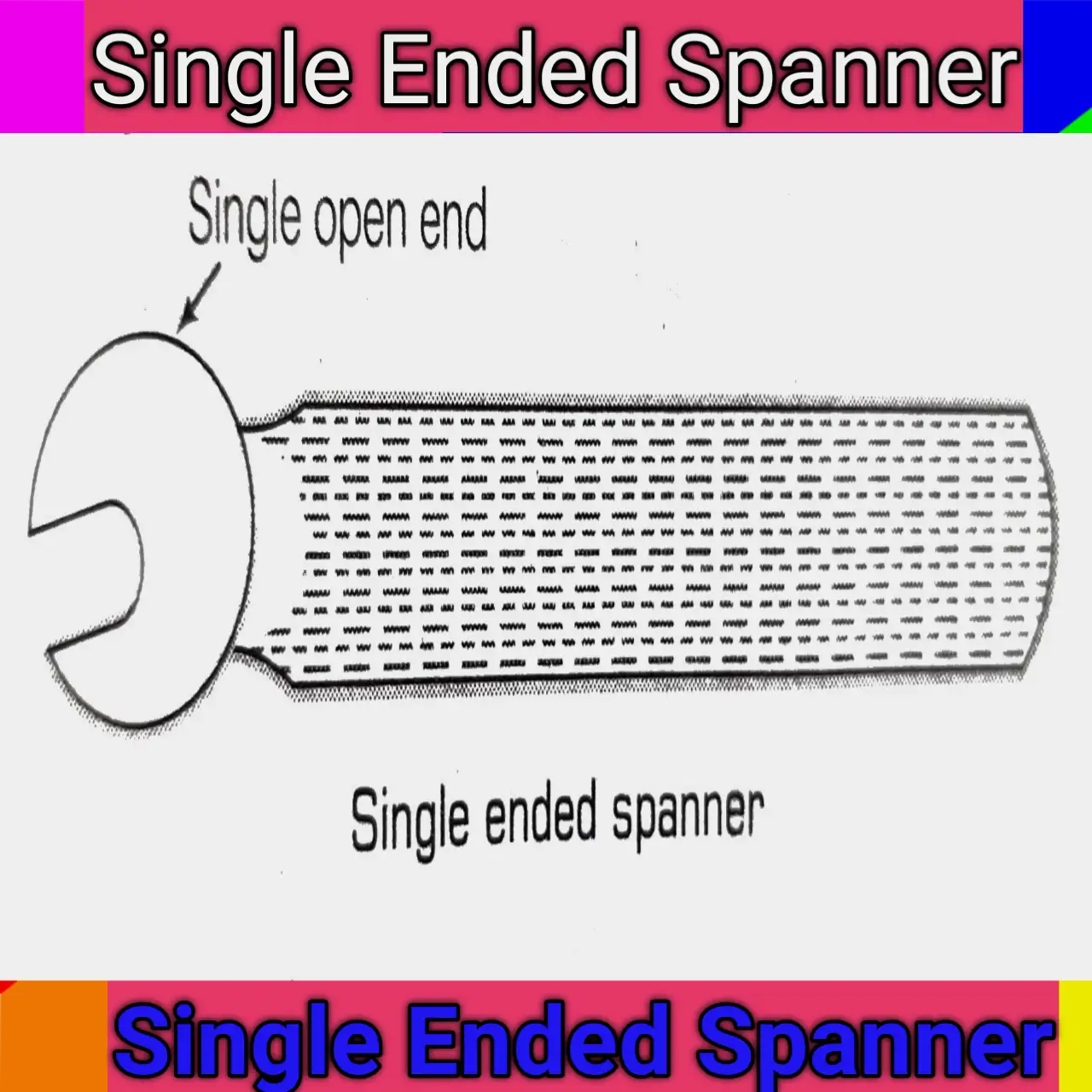

(a) Single Ended Spanner

The single-ended spanner has one curved at one end as its name. I can hold only one nut and bolt head.

Advantages:

- Simple and sturdy design

- Typically stronger than double-ended spanners

Disadvantages:

- Limited to one size

- Less versatile than double-ended spanners

(b) Double Ended Spanner

As such its name, a double-ended spanner has two curves at both ends. Therefore, two different sizes of bolt heads can be gripped.

Advantages:

- Provides two different sizes

- More versatile

Disadvantages:

- Can be bulkier than single-ended spanners

- Slightly weaker at the joint

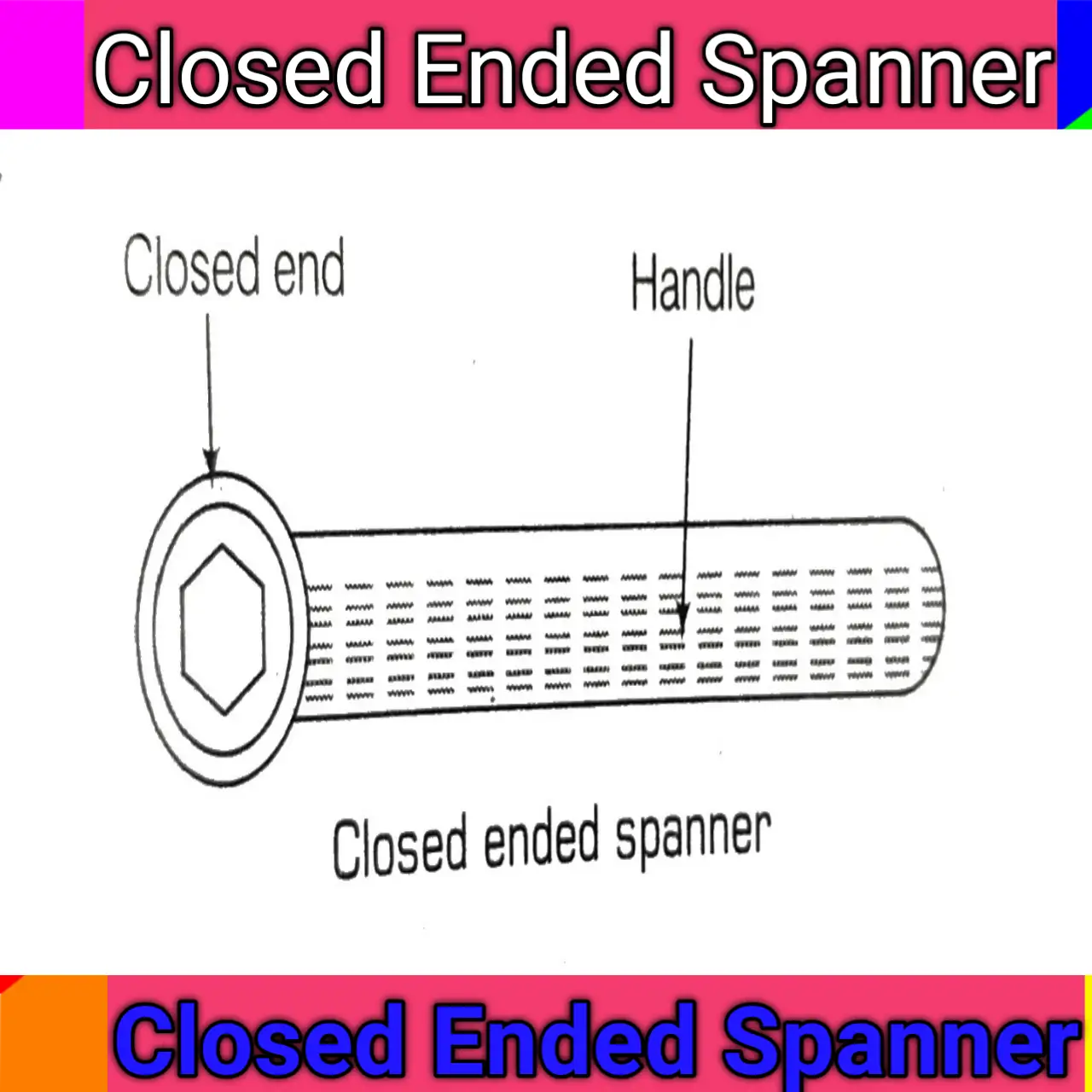

(ii) Closed-Ended Spanner

This type of spanner head is closed as shown in the figure. On the head of one side, it has a circular ring. Inside a hexagonal or square type shape or according to bolt, the ring of the shapes is designed.

Advantages:

- Provides a firm grip on nuts and bolts

- Less likely to slip off

Disadvantages:

- Harder to use in tight spaces

- Limited to specific sizes

(iii) Combination Spanner

It has a combination of both open-end spanners and another box-end spanner. Therefore, it is used to open a tight one size of nut and bolt.

Advantages:

- Combines the benefits of open and closed-ended spanners

- Versatile and convenient

Disadvantages:

- Can be bulkier

- May be less strong at the joint

(iv) Ring Spanner

It has holes at both ends. These holes have 12 notches, which are helped to grip the bolt or nut. This spanner is used in the complex form of nuts and bolts, where open-ended spanners are not possible. It is widely used in automobile machine shops.

Advantages:

- Excellent grip

- Reduces the risk of rounding off nuts and bolts

Disadvantages:

- Difficult to use in tight spaces

- Limited to specific sizes

(v) Face Spanner

Its shape is such as the alphabet U. It has two pins. If you want to open the nuts or bolts then use the face spanner to hold the head of the nut or bolt. The face spanner consists of pins that help you to easily open or tighten the nuts and bolts.

Advantages:

- Ideal for specific applications like bicycle repairs

- Provides a good grip

Disadvantages:

- Limited to specialized uses

- Not very versatile

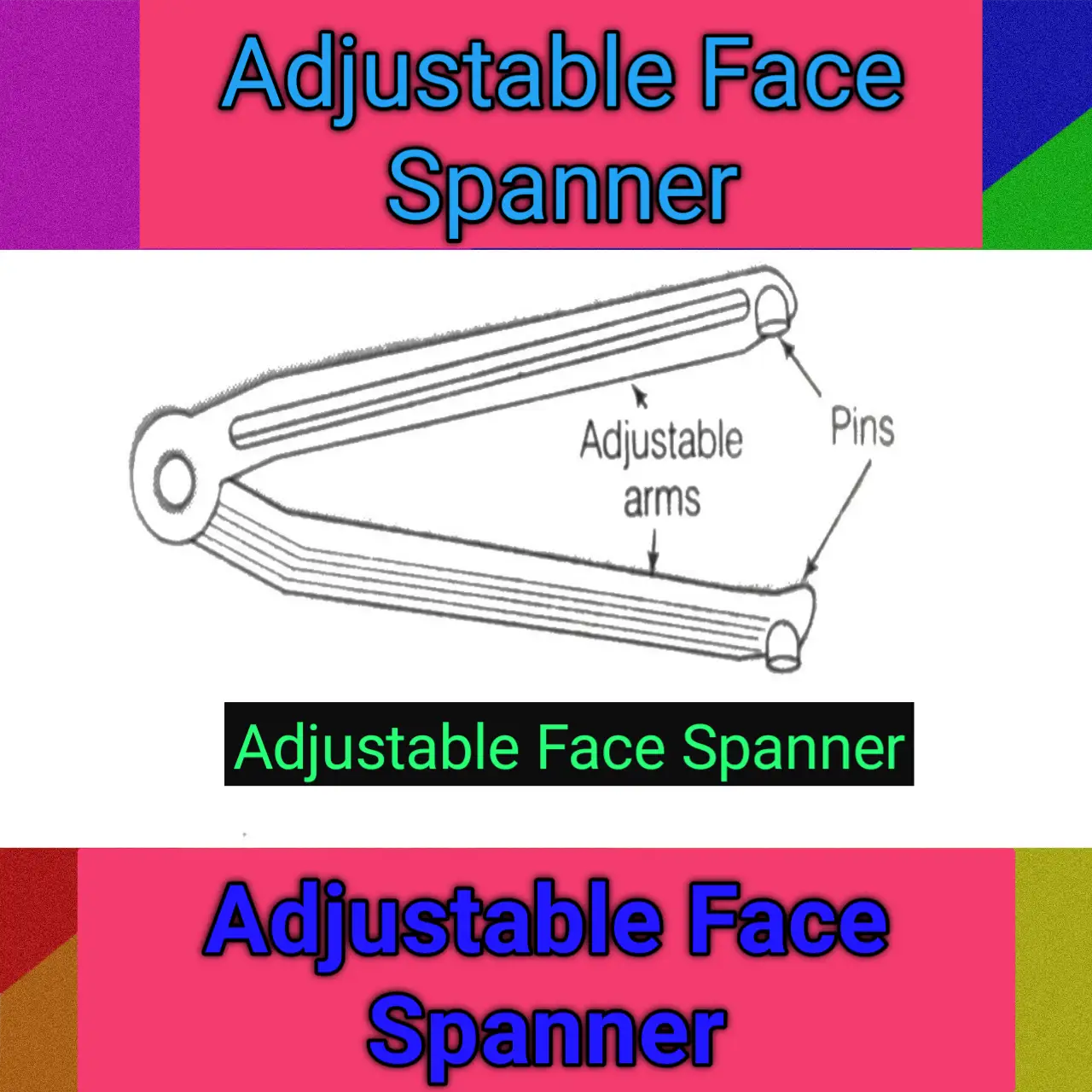

(vi) Adjustable Face Spanner

It is similar to a caliper or divider, in which one head is attached by a rivet and other heads one-one pins respectively, and according to need, the distance between these pins may increase or decrease. So that, it can open any nut or bolt.

Advantages:

- Adjustable to fit various sizes

- Versatile

Disadvantages:

- Can be less stable than fixed spanners

- May not fit as precisely

(vii) Hook Spanner

This spanner is half round from one side with the hook at 90° on its end as shown in the figure. The hook spanner is used for opening or tightening round-shaped nuts or bolts.

Advantages:

- Useful for adjusting threaded collars and retaining rings

- Simple design

Disadvantages:

- Limited to specific uses

- Less versatile

(viii) Adjustable Hook Spanner

It is designed for the safe and easy tightening and loosing of lock nuts and is used in bearing. It includes four different sizes ie, covering twenty-four nut sizes. It is made of special hard steel.

Advantages:

- Adjustable to fit various sizes

- Versatile

Disadvantages:

- Less stable than fixed hook spanners

- May not fit as precisely

(ix) Adjustable Spanner

As the indicates, it is used for various sizes of nuts or bolts, and its open head size can increase or decrease according to the size of nuts and bolts. One jaw is movable and the other is stable and is adjusted through the screw. This is used in light work and is available in sizes such as 150 mm, 300 mm, etc.

Advantages:

- Adjustable to various sizes

- Highly versatile

Disadvantages:

- Can be bulky

- May not grip as securely as fixed-size spanners

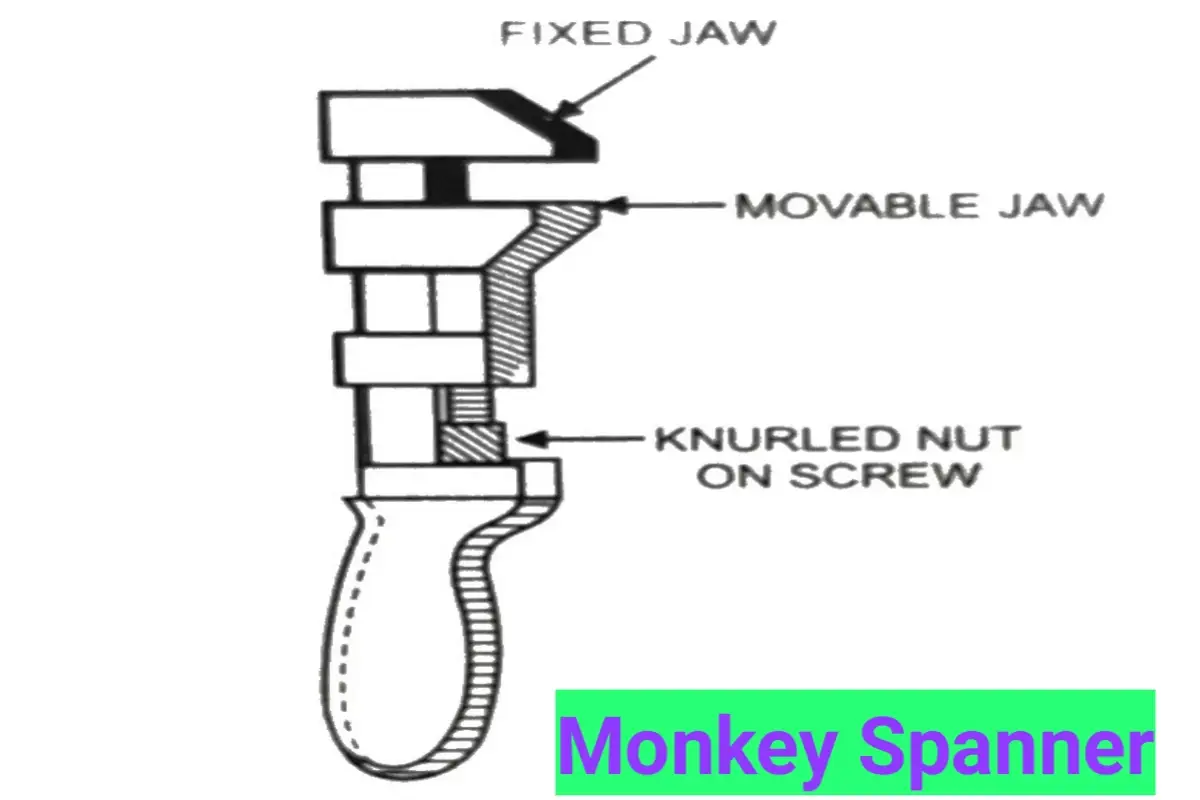

(x) Monkey Spanner

It is also used for variable sizes of nuts and bolts to be opened or tightened and its jaw stands at 90° with its body. It works also as an adjustable spanner. The movable jaw of this spanner has threads like the pipe spanner and more strong as compared to the adjustable spanner. It can be adjusted with a round pipe and nuts as well as a screw wrench.

Advantages:

- Adjustable to fit various sizes

- Strong and durable

Disadvantages:

- Can be heavy and bulky

- May not fit as precisely as fixed-size spanners

(xi) T-Socket Spanner

Its shape is like an English alphabet letter T and is used to open or tighten the nut in depth. A T-socket spanner has one head structure such that the socket, according to the size of nuts/bolts and the second head has a handle. In this spanner, different types of sockets are used for fastening the different types of nuts and bolts.

Advantages:

- Provides good torque

- Comfortable to use

Disadvantages:

- Limited to specific sizes

- Less versatile

(xii) Offset Socket Spanner

This type of spanner has an English alphabet L shape. Its neck is turning at 90°, which uses such as the handle shown in the figure. It is widely used in the motor in the workshop for opening or removing the very tightening nuts or bolts. It has a hole in one hand, those fitted on the nut head, and the second end used for applying force.

Advantages:

- Good for reaching recessed nuts and bolts

- Provides good leverage

Disadvantages:

- Limited to specific sizes

- Can be bulky

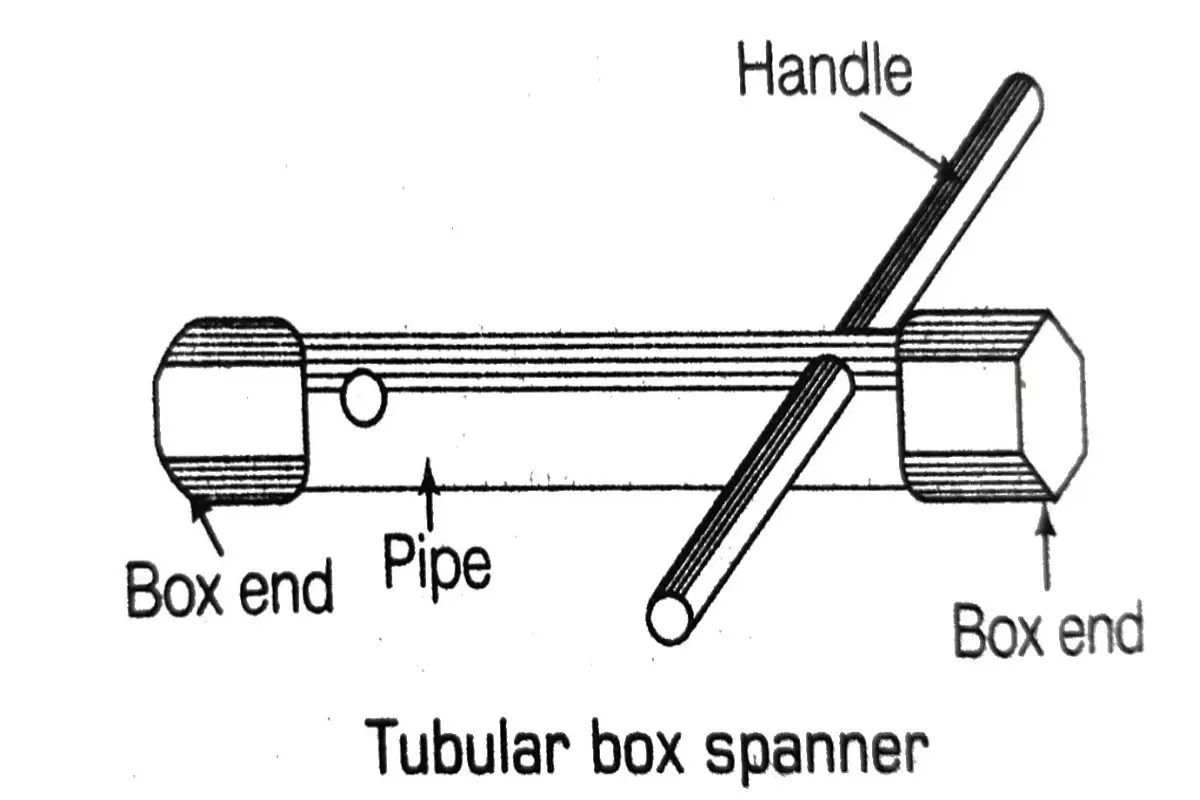

(xiii) Tubular Box Spanner

It is used for hexagonal nuts or bolts, which are to be fitted in some more depth. It is widely used in the automobile workshop.

Advantages:

- Lightweight

- Provides good grip on nuts and bolts

Disadvantages:

- Limited to specific sizes

- Can be difficult to use in tight spaces

(xiv) Ratchet Wrench

It is a hand tool made from metal. A handle is attached to a socket which is used to open or tighten the nuts and bolts.

The Ratchet wrench has two parts a ratchet handle and a box spanner or socket nuts or bolts.

Advantages:

- Allows for continuous motion without removing the wrench

- Provides good torque

Disadvantages:

- Can be complex and more prone to failure

- Bulkier than standard spanners

(xv) Chain Pipe Wrench

It is used to open or tighten the pipes, where a pipe wrench cannot work. It has a chain that can be fixed in two plates by rivets. The chain is given a round grip of the pipe and tightened by plates.

Advantages:

- Good for gripping round objects

- Adjustable to different sizes

Disadvantages:

- Can damage the surface of the object

- Less versatile for other applications

(xvi) Pipe Wrench

It is made up of forged steel and is used for opening or tightening its pipe sockets and round pipes. In a pipe wrench, the jaw has two parts, one is stable and the second is movable which is easily moved in forward and backward directions with the help of a screw joint. Both sides have grooves, which help to hold a job easily.

Advantages:

- Good for gripping round objects

- Adjustable to different sizes

Disadvantages:

- Can damage the surface of the object

- Less versatile for other applications

(xvii) Strap Wrench

When you use a pipe wrench or chain pipe wrench then it marks on the pipe surface, so to avoid this defect, we must use a strap wrench.

The strap wrench has a convex belt at one end of the handle and a clip for tightening the belt by rotating around the pipe.

Advantages:

- Good for gripping irregular shapes and delicate surfaces

- Adjustable to different sizes

Disadvantages:

- Limited to specific applications

- May not provide as much torque

(xviii) Allen Key

It is hexagonal and fits into the holes in safety set screws or socket-heat set screws. This Allen is made of steel in a hexagonal shape that is bent at 90°. This is available in 2 mm. It has the English letter L shaped.

Advantages:

- Simple and lightweight

- Ideal for hexagonal socket screws

Disadvantages:

- Limited to specific screw types

- Provides less torque

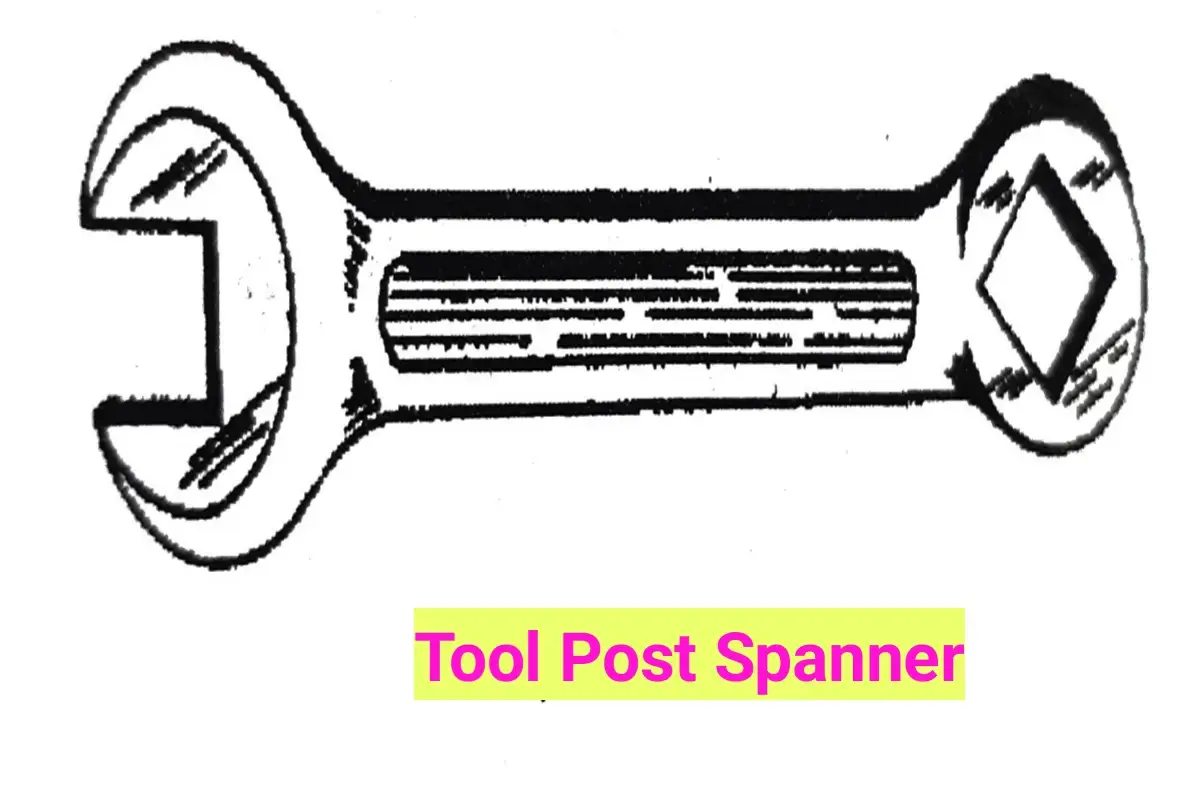

(xix) Tool Post Spanner

This is a combination spanner but is used in lathe machine operation to tighten the tools in the tool post.

Advantages:

- Designed for use with tool posts

- Provides a secure grip

Disadvantages:

- Limited to specific applications

- Less versatile

(xx) Lever Jaw Wrench

It is a simple machine, which can be part of more complex mechanical devices. The basic lever consists of a stuff bar or rod in place across the load. It is used easily to remove stuck, rusted, and stripped screws, nuts, and bolts.

Advantages:

- Provides a strong grip

- Adjustable to different sizes

Disadvantages:

- Can be bulky

- May damage surfaces

(xxi)Socket Spanners

These spanners are generally used where a hexagonal bolt or nut is to be fitted in some less depth.

Advantages:

- Provide good grip and torque

- Available in various sizes

Disadvantages:

- Requires a ratchet handle

- Can be bulky and heavy

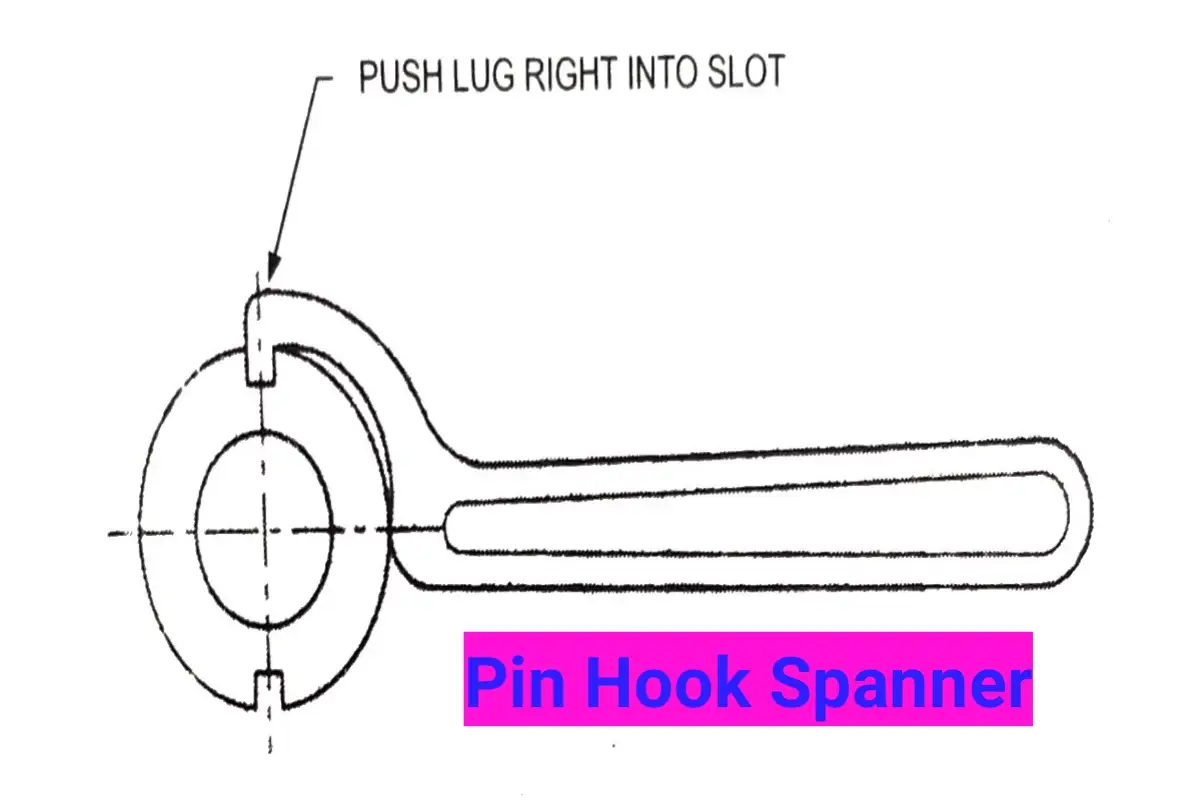

Pin Hook Spanners

It is also called a ‘C’ spanner which is generally used on circular nuts having a slot.

Advantages:

- Ideal for specific types of fasteners

- Provides precise control

Disadvantages:

- Limited to specific applications

- Not versatile for general use

Size and Identification of Spanners/Wrenches

Spanners/wrenches for metric nuts, bolts, and screws are marked with the size across the jaw opening in mm. E.g. single-ended spanner 12mm.

The following care should be taken when using spanners/wrenches:

- Always select a spanner/wrench, which fits the nut or bolt properly.

- It is safer to pull rather than push on a spanner/wrench.

- Be sure that the nut is fully seated in the spanner jaw.

- Use the spanner/wrench in the same plane as the nut or bolt head.

- When tightening or loosening a nut, a sharp quick jerk is more effective than a steady pull.

Defects in Spanners/Wrenches

Spanners/Wrenches have their jaws slightly wider than the width of the nut to place them into the position easily. While using place the spanner/wrench so that its jaws bear fully on the flats of the nut. The incorrect use damages the spanners/wrenches. Defective spanners are dangerous for use, therefore the use of defective spanners/wrenches should be avoided.

Generally, the following defects are found in spanners/wrenches:

In the open-ended spanners/wrenches, the following defects are found:

(a) Crack

(b) Jaws sprung

(c) Jaws worn out and rounded.

In the ring spanners/wrenches, the following defects are found:

(a) Crack

(b) Worn out and rounded internal serrations.

In the socket spanner/wrenches, the following defect is found:

(a) Worn out and rounded internal serrations.

In the tubular box, spanners/wrenches following defects are found:

(a) Split corner

(b) Hexagon worn out and rounded.

Precautions While Using a Spanner/Wrench

(1) A wrench should not be used as a hammer and never strike it.

(ii) Kerosene oil should be used on rusty nuts and bolts before loosening the nut and bolt.

(iii) It is a dangerous practice to lengthen the wrench handle for additional leverage. Use a larger spanner/wrench.

(iv) Choose a spanner/wrench that fits properly. A loose-fitting wrench may slip and round off the corners of the bolt head and nut.

(v) When using a spanner/wrench, clean the grease or oil from the floor in the work area. This will reduce the possibility of slipping and losing balance.

Conclusion

Choosing the right spanner is a skill that hinges on the particular job at hand. By understanding the strengths and weaknesses of each spanner type, you can assemble a toolkit tailored to the wide array of challenges your projects may present. Knowing the unique features of these versatile tools enables you to tackle different tasks effectively and with accuracy.