The importance of Engineering drawing knowledge and practice is a must for designing or producing a component or part. The economic success of any country is mainly dependent on its industrial development. Due to globalization, the products of any industry of our country are expected to be of a global market standard, due to the above-said reason our Indian product is required to be of very high quality concerning size dimension, fit, finish, etc.

To produce the best standard product all the technical personnel (Engineers to Craftsmen) in an industry must have sound knowledge of engineering drawing because engineering drawing is the language of engineers. Engineering drawing is a universal language with different types of lines and alphabets. Technical personnel in any industry including craftsmen are expected to communicate anything concerning a part or a component by drawings involving lines, symbols, abbreviations, etc.

With our spoken languages, it is impossible to express the details of a job or a product. Engineering drawing knowledge and practice is a must for designing or producing a component or part. Even a small mistake in the drawing may reflect very badly on the product. Therefore reading and doing engineering drawings are essential for craftsmen and engineers.

One picture is worth one thousand words.

Engineering Drawing equipment – Drawing board, ‘T’ square

The following are the commonly used equipment in a drawing office.

Engineering Drawing board:

Drawing board is one of the main equipment of Draughtsman. It is used for supporting the drawing paper/tracing paper for making drawings. It is made of well-seasoned wood strips of about 25 mm thick or masonite, free from knots and warping. It should be softer enough to allow insertion and removal of drawing pins. Two battens are fastened to the board by screws, in slotted joints. They prevent warping and at the same time permit expansion and contraction of the strips due to the change of moisture in the atmosphere.

One of the shorter edges of the drawing board is provided with an “ebony edge” (hardwood) fitted perfectly straight, on which the stock of the ‘T’square slides. It projects about 4 to 5 mm from the board. While working, the ebony (working) edge side is to be placed to the left side, on a table or castle at a convenient height and slope.

Standard drawing boards are designated as follows as per IS:1444-1989.

| SI. No. | Designation | Size (mm) |

| 01 | D₀ | 1500 x 1000 x 25 |

| 02 | D₁ | 1000 x 700 x 25 |

| 03 | D₂ | 700 x 500 x 15 |

| 04 | D₃ | 500 x 350 x 15 |

The working edge (ebony) must be straight. It should be tested with a straight edge or by a ‘T’ square working edge.

Nowadays drawing boards are available with laminated surfaces. The flatness can be checked by placing a straight edge on its surface. If no light passes between them, the surface is perfectly flat.

‘T’square:

It is of ‘T’ shape, made of well-seasoned wood. It has two parts, a head and a blade. One of the edges of the blade is the working edge. The blade is screwed to this head such that the working edge is at the right angle to the head.

The standard ‘T’ squares are designated as follows with dimensions shown in mm; as per IS:1360-1989.

| S.No. | Designation | Blade length |

| 01 | T₀ | 1500 |

| 02 | T₁ | 1000 |

| 03 | T₂ | 700 |

| 04 | T₃ | 500 |

The ‘T’ squares are used with their heads against the ebony edge of the drawing board to draw horizontal lines, and parallel lines and to guider-hold the set squares, stencils, etc.

T square should never be used as a hammer or as a guide for trimming papers.

Pencils, Grade, and Selection – Use of Eraser

The following are the commonly used equipment in a drawing office.

Engineering Drawing Pencils:

In the drawing section, standard pencils (lead encased in wood) and semi-automatic pencils are used. Pencil leads are made of graphite with kaoline (clay) of varying amounts to get the desired grades. The higher the kaoline higher the hardness.

Engineering Drawing Grades of pencils:

Pencils are graded according to the hardness or softness of the lead. The hardest pencil is 9H grade and the softest pencil is 7B grade. The selection of the grade of pencils depends on the type of line work required and the paper on which it is used.

Softer lead pencils are used to produce thicker and darker line work, but they wear out quickly. Medium grades of H and 2H are used for general line work as well as for lettering.

Harder grade leads produce lighter and thinner lines. Most construction line work is done with 4H, 5H, and 6H pencil leads, producing thin but also sufficiently dark by exerting pressure. Depending upon the individual’s touch and the style of writing, the right pencil may be selected.

For any drawing on drawing paper or tracing paper, lines should be black, particularly drawings to be reproduced. For this purpose, the pencil chosen must be soft enough to produce jet-black lines as well as hard enough not to smudge easily. The point should not crumble under normal working pressure. The pencils should not be hard and cut grooves on the paper while drawing with normal pressure, Pencils H, 2H, or 3H depending upon the paper (quality) and weather conditions selected.

In summer the pencil leads become softer due to the temperature rise, so slightly harder pencils can be made use of. Softer-grade pencils are used on smooth surfaces for lettering and arrowhead. During the rainy season or when humidity is higher, pencil leads become harder. So softer pencils are to be used. Whatever be grade of pencil you use, always prefer quality pencils/leads viz., Venus, Kohinoor, apsara, etc.

For better line work, i.e., dense black lines, prefer paper that does not have too much roughness.

Engineering Drawing Selection of pencils:

Pencil grades vary from one brand to another brand. Select the grades of the pencil depending on the type of line work. For construction construction lines, you can choose 2H or 3H, for lettering and object lines grade H pencils. In general H, HB, and 2H are used.

H medium hard

HB medium soft

2H hard

Pencils used for drawing are always hexagonal in cross sections as they do not roll easily even when they are placed on slope surfaces. Its cross-section helps in rotating the pencil while drawing lines, to give uniform line thickness.

Nowadays automatic (Mechanical) pencils or clutch pencils are available in different sizes (lead dia 0.3,0.5,0.7 or 0.9 mm). They are easy to handle as there is no reduction of holding length pencil leads that can be replaced, as per the required grade of hardness. They produce lines of uniform width without sharpening.

Engineering Drawing Erasing Shield:

When, on a drawing, a part of a line or some lines among many other lines need to be erased or modified, the normal way of erasing will damage the other nearby lines. In such a situation an erasing shield is effectively useful. It is a thin metallic sheet having small openings of different sizes and shapes. A suitable opening is aligned to the line to be erased and the line is removed by the eraser.

Engineering Drawing Setsquare (IS:1361-1988):

Transparent celluloid/Plastic set squares are preferred. They are two in having one corner with 90°. The set square with 60°- 30° number, each 25 cm long and 45° or 20 cm long is convenient for use. Set squares sometimes lose their accuracy due to internal strains. So they should be tested periodically.

Sometimes set squares have French curves. Set squares are used to draw all straight lines except horizontal lines. It is convenient to draw horizontal lines using a ‘T’ square.

With the help of the ‘T’ square and manipulating 45°, 30°, and 60° set squares, angular lines in the multiples of 15° can be drawn. Parallel lines and perpendicular lines to a given inclined line can also be drawn using set squares and ‘T’ squares.

Set squares with graduated, bevel edge, and French curve openings are preferable. They are also used to draw smooth curves. Setsquare should never be used as a guide for trimming papers.

Engineering Drawing Scales:

Scales are used to transfer and or to measure the dimensions. They are made of wood, steel, ivory, celluloid, or plastic. Stainless steel scales are more durable. They are either flat, bevel, or triangular cross-sections. Scales of 15 cm long, 2 cm wide, or 30 cm long and 3.5 cm wide flat scales are in general use. Thin section or bevel-edged scales are preferred over thick flat scales. Parallax error will be nil or least while using thin/tapered edge scales.

Engineering Drawing office materials

Engineering Drawing paper: These are of two types:

Hand-made paper

Mill-made paper

Hand-made papers have rough surfaces, are pale in color, and are not used for regular work, but are meant for charts.

Mill-made papers are most commonly used for regular work and are available in different sizes and rolls. They are specified by their weight in kg per ream or density in grams per square meter.

Size of engineering drawing sheets (in mm):

While working or handling, the papers are liable to tear on the edges. So slightly larger size (untrimmed) sheets are preferred. They are trimmed afterward. IS:10811:1983 lays down the designation of preferred trimmed and untrimmed sizes.

The basic principle involved in arriving at the sizes of the drawing paper is as under. The area of the biggest size (A) is 1 m² and its length and breadth are in the ratio 1: √2. Let

x and y be the sides of the paper. The surface area of A0 is 1m², then the sides are x = 0.841 m and y = 1.189 m.

Two series of successive sizes are obtained by either halving or doubling along the length. The area of the successive sizes is in the ratio of 1:2.

Designation of sheets:

The drawing sheets are designated by symbols such as A₀, A₁, A₂, A₃, A₄, and A₅. A₀ being the largest. The table below gives the length and breadth of the above sizes of sheets. (Trimmed and untrimmed)

The relationship between two sides is the same as that of a side of a square and its diagonal.

| Designation | Trimmed size | Untrimmed size |

| A₀ | 841 x 1189 | 880 x 1230 |

| A₁ | 594 x 841 | 625 x 880 |

| A₂ | 420 x 594 | 450 x 625 |

| A₃ | 297 x 420 | 330 x 450 |

| A₄ | 210 x 297 | 240 x 330 |

| A₅ | 148 x 210 | 165 x 240 |

Protractor:

A protractor is an instrument for measuring angles. It is semi-circular or circular and is made of a flat celluloid sheet.

The angles can be set or measured from both sides, aligning the reference line and point ‘0’ with the corner point of the angle. A protractor can also be used to divide a circle or draw sectors.

Engineering Drawing Instruments – Features and their uses

The quality of a good drawing does not only depend on the talent of the craftsman but also on the quality of the instruments he uses.

Drawing instruments are generally sold in sets in boxes, but they are also available separately. The main parts of high-grade instruments are generally made of nickel or brass. They must be rust-proof. Tool steel is used for making the blades of the inking pen, bow instruments, and various screws.

An instrument box contains the following:

- Large compass (with attachment facility)

- large divider

- Bow compasses, bow dividers

- Lengthening bar

- Pen point for attachment

- Screwdriver

- Lead case

- Liner

Large compass:

It has a knee joint in one leg that permits the insertion of a pen or pencil point or attaching a lengthening bar with a pen or pencil point attached to it. It is used for drawing large circles/arcs and also for taking large measurements. The pin on the other leg can be swiveled to a vertical position when drawing large circles, while drawing the circles of arcs it should be held in such a way that the needlepoint leg and pencil point leg should be bent to make it perpendicular to the paper.

As a rule, while drawing concentric circles, small circles should be drawn first before the center hole gets worn.

Large divider:

It is used to transfer dimensions and divide lines into several equal parts. A divider with adjustable joints is preferable rather than plain legs.

Bow instruments:

Bow pencil and bow pen compass are used for drawing circles of approximately 25 mm radius. A bow divider is used for marking or dividing smaller spaces There are two types (i) Integral legs with spring action (46) and (ii) two legs held with a curved spring on top with the handle on it.

Bow instruments may have to adjust the wheel and nut. To draw circles, it is better to mark the required distance separately set the instruments, and check. Then only the circles or arcs should be drawn on the drawing.

Different types of bow instruments. Adjustments should be made with the thumb and middle finger. The instrument is manipulated by twisting the knurled head between the thumb and finger.

Drop spring bow pencil and pen:

Drop spring bow pencils and pens are designed for drawing multiple identical small circles. Example: rivet holes, drilled/reamed holes. The central pin is made to move freely up and down through the tube attached to the pen or pencil unit. It is used by holding the knurled head of the tube between the thumb and middle finger while the index finger is placed on the top of the pin. The pinpoint is placed on the center point of the circle to be drawn and a pencil or pen is lowered until it touches the paper. The instrument is turned clockwise and the circle is drawn.

Inking pen or liner or ruling pen:

It is used to ink the straight lines drawn with the instruments but never for free-hand lines or lettering.

Lengthening bar:

To draw larger circles, it is fitted to the compass. The pencil point or pen point is inserted into its end.

Replaceable spare pencils, pens, and needle points for the compass are available in the instrument box.

Types of Lines and Angles

A point represents a location in space, having no width or height. It is represented by drawing the intersection of lines or a dot.

The line is the path of a point when it moves. It has no thickness and is of two types:

Straight line

Curved line

Straight line:

It is the path of a point when it is moving in a particular direction. It has only length and no width. Also, a straight line is the shortest distance between two points. Straight lines, depending on their orientation are classified as Horizontal, Vertical, and Inclined or Oblique lines.

Horizontal line:

Horizontal lines are those which are parallel to a horizontal plane. An example of the horizontal plane is the surface of still water.

Vertical line:

Lines that are perpendicular to horizontal lines are called vertical lines. It can be treated as a line along the plumb line of the plumb bob or parallel to a plumb line.

Inclined line or Oblique line:

A straight line that is neither horizontal nor vertical is called an inclined line.

Curved line:

It is the path of a point that always changes its direction.

Parallel lines:

They are the lines with the same distance between them. They may be straight lines or curved lines Parallel lines do not meet when extended.

Perpendicular lines:

When two lines meet at 90°, the two lines are said to be perpendicular to each other. One of these lines is called a reference line.

Engineering Angles:

Angle is the inclination between two straight lines meeting at a point or meeting when extended. AB and BC are two straight lines meeting at B. The inclination between them is called an angle. The angle is expressed in degrees or radians.

Concept of a degree:

When the circumference of a circle is divided into 360 equal parts and radial lines are drawn through these points, the inclination between the two adjacent radial lines is defined as one degree. Thus a circle is said to contain 360°.

Acute angle:

If an angle which is less than 90° is called an acute angle.

Right angle:

The angle between a reference line and a perpendicular line is called the right angle.

Obtuse angle:

This refers to an angle between 90° and 180°.

Straight angle:

This refers to an angle of 180°. This is also called the angle of a straight line.

Reflex angle:

It is an angle that is more than 180°.

Adjacent angles:

These are the angles lying on either side of a line.

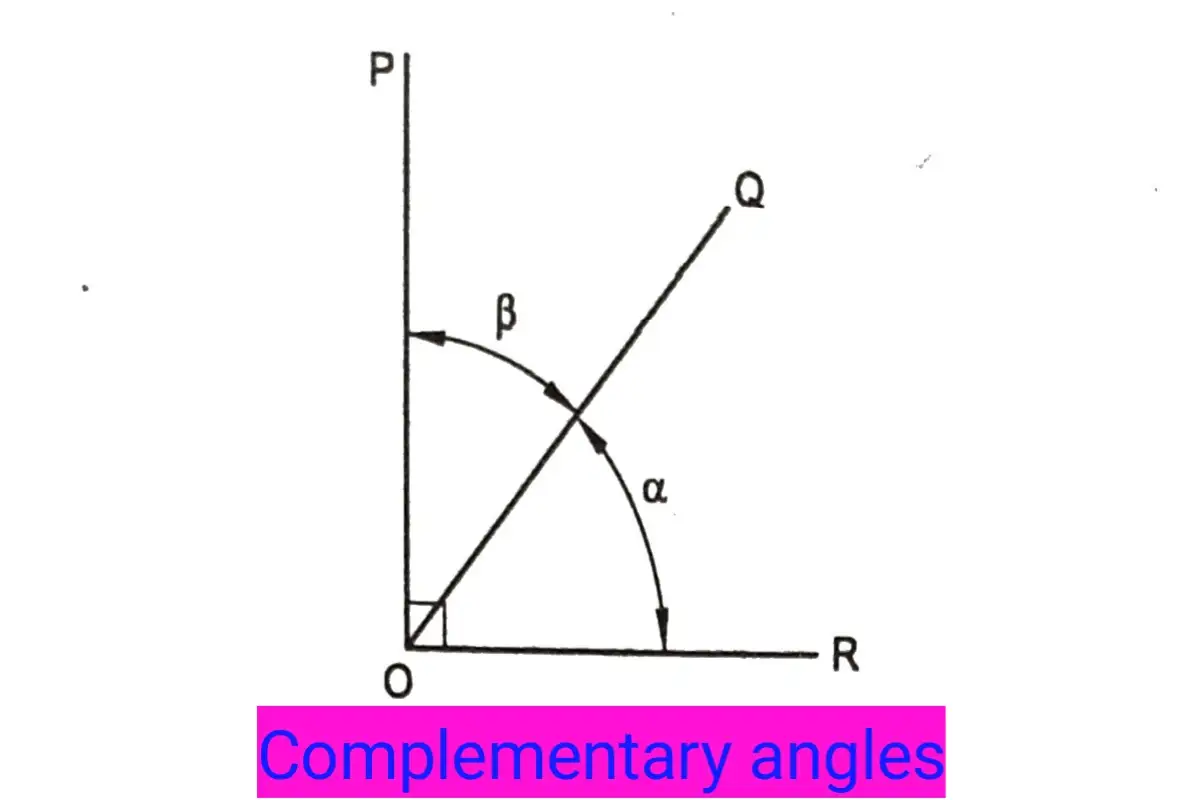

Complementary angles:

When the sum of the two angles is equal to 90°, angle POQ + angle QOR=90° angle POQ, and angle QOR are complementary angles to each other.

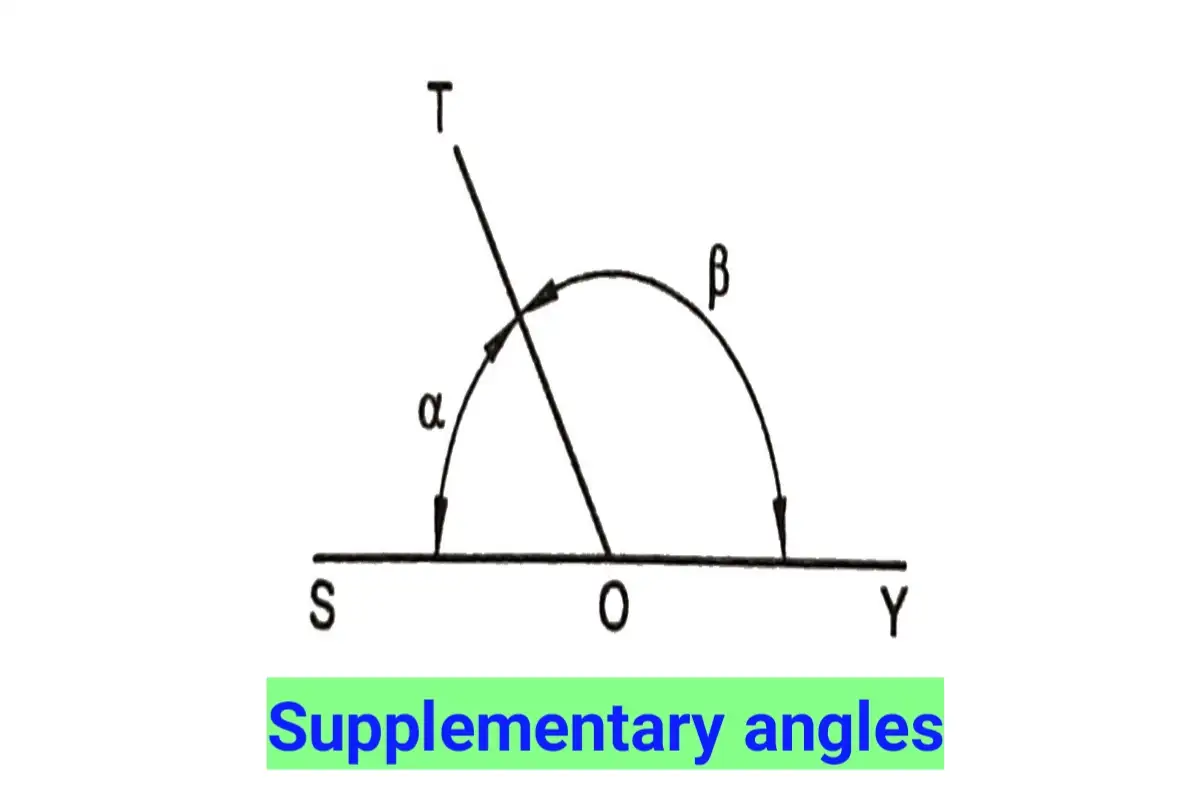

Supplementary angle:

When the sum of the two adjacent angles is equal to 180°, for example, angle SOT + angle TOY = 180°, angle SOT and angle TOY are supplementary angles to each other.