A marking block is used for drawing the parallel line of any one side of the job. It is also known as a surface gauge or scribing block. Its block is made up of cast iron, which is attached to a rock stand to do work and slides a scriber holder. So that, it can be set at any height with the help of a nut. Its scriber is straight standing in at one edge and bent at 90° of the other edge.

The surface gauge is an instrument used on a surface plate for scribing lines in layout work. It consists of a heavy base and an upright spindle to which a scriber is clamped.

The base of the surface gauge has a V-groove which allows it to be used on cylindrical work as well as on flat surfaces. There are also pins in the base, which may be pushed down so that the surface gauge can be used against the edge of a surface plate or a slot. A surface gauge can also be used as a height gauge and for leveling work in vice.

2 Types of Marking Blocks in Workshop

Marking blocks are two types

(i) Fixed Marking Block

(ii) Universal Marking Block

(i) Fixed Marking Block/Scribing Block Diagram

In a fixed marking block, the pillar is attached to the base in the perpendicular direction, where the scriber can be slid in up and down directions. It is also used in four chuck lathe machines for the job of chucking.

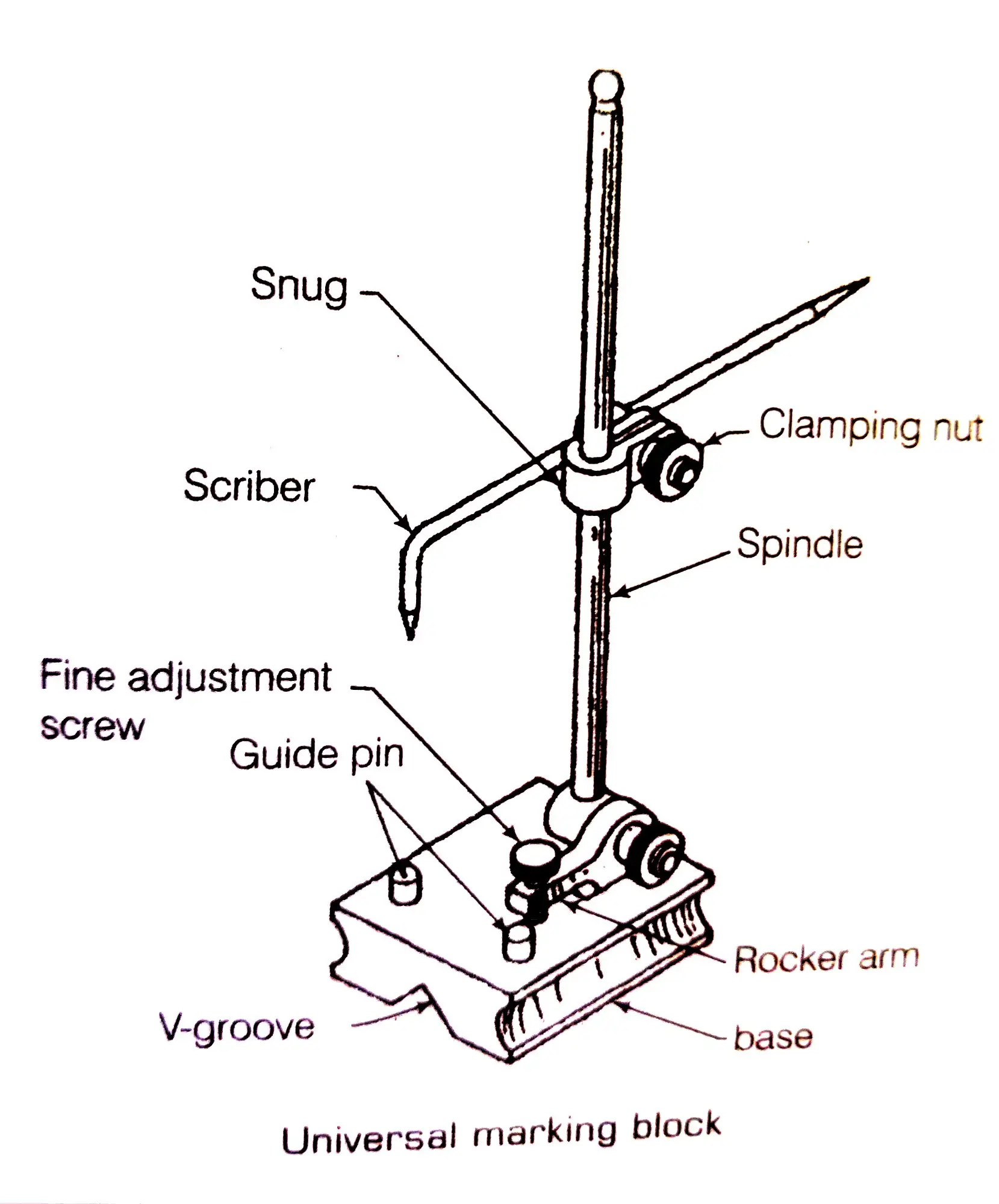

(ii) Universal Marking Block/Universal Scribing Block Diagram

In the universal marking block, the pillar does not fit in the base. The pillar is fitted into the rocker’s arm with the help of a nut and another head of the rocker’s arm is attached with an adjusting screw.

When we turn the screw, the scriber is moving up and down direction. The lock nut is used for adjusting a scriber. The universal marking block has done fine marking as compared to the fixed sign block.

Marking Block for Lathe Machine

(i) Surface gauge is used to draw parallel lines of the base on the job surface.

(ii) To find out the center of the circle or cylindrical job.

What is the Marking Method

- Clean the surface plate.

- Select surface gauge, angle plate, or V-block and steel rule according to the size of the job. If possible use the rule in the square head of the combination set.

- Hold the steel rule by supporting it with the angle plate.

- Loosen the clamping nut of the scriber snugly adjust the scriber approximately and tighten it.

- Use a fine-adjusting screw to take the correct measurement.

- Remove the steel rule place the workpiece and mark lines on it. While marking, odd-shaped jobs should be clamped on an angle plate and round jobs should be supported on V-block.

Universal marking block me research

Your positive feedback motivates me to keep up the good work.

Please read this article.Universal marking block