The Engineering key is a machine element, which is used to connect a rotating machine element at a shaft. Keys are used to transmit torque from a rotating machine element at the shaft or we can also conclude that keys are used to locate pulleys or gears on a shaft and prevent relative motion between them. It is generally made up of mild steel.

Keys have their first half part under the keyway and the second half under the hubway of a pulley shaft. Under consideration of the fitting of the keys. It is of two types, i.e.,

Keys have their first half part under the keyway and the second half under the hubway of a pulley shaft. Under consideration of the fitting of the keys. It is of two types, i.e.,

- Sunk key

- Saddle key

1. Sunk Key

The keys, which are fitted at the shaft in a keyway are called sunk keys. Sunk keys are mostly used in all types of operations. There are many types of sunk keys, which are as follows.

(i) Feather Key

This type of key is equal in length and breadth and does not contain a taper. Both heads have circular or rectangular shapes. The feather key is used to stop the relative rotary motion between the shaft and the power transfer.

It fails to stop the relative axial motion between the shaft and hub, so that the key is jammed at the shaft or hub. It has a relative part of a keyway, i.e., a cutting part that contributes to its stability.

Some rules for the stability of the feather key are discussed below.

(a) In the key, a peg is made on it so that the hub or shaft is fitted in a groove.

(b) A square head is tightened with a key by a through screw.

(c) In the feather key, make a head on both sides, which the hub is holding.

(d) The feather key can easily be used, such as the Dovetail cross-section key.

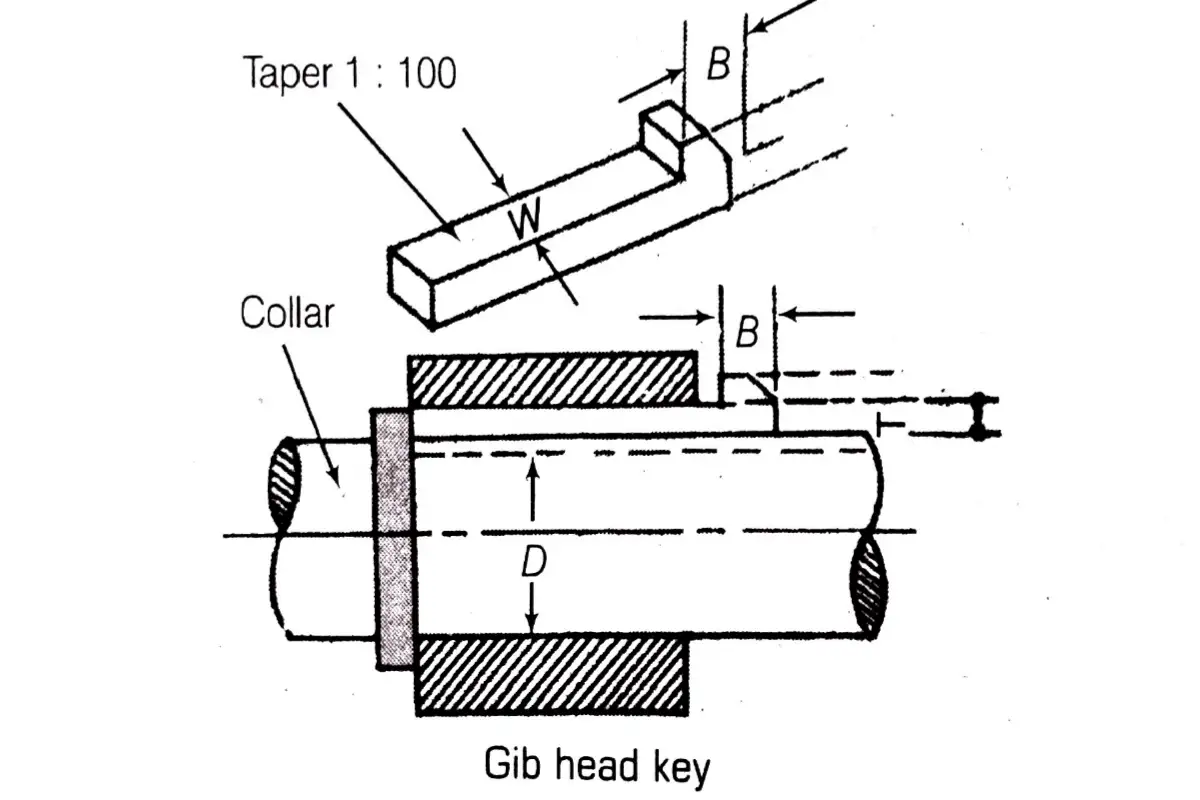

(ii) Gib Head Key

This is a tapered key as shown in the figure. It is used to tighten the pulley at the shaft head. If it is used in the middle, then needs a long keyway and stops both the shaft and gear, which means that stops the axial motion and rotational motion. The breadth of the gib head key is 1:100 of taper.

(iii) Woodruff Key

Woodruff keys are semicircular in shape, such that when installed, they leave a protruding tab. The keyway in the shaft has a semicircular pocket. The mating parts have a longitudinal slot.

It eliminates the milling of a keyway near the shaft shoulders, which have already stress concentration. This is the main advantage of the woodruff key. It is used to assemble the components at a shaft by fitting them into a matching curved key slot.

(iv) Round Key

The round key is more useful for light power transmission, and its shape such as cylindrical or conical. It is fitted in a shaft or hub in two types. One is perpendicular and the other is axial. It is also called a pin key. The advantage of this type of key is that the stress connection induced due to the key is significantly much less.

(v) Plane Key

Its breadth and length are equal to each other, so that it may be parallel, such as taper red, and it is stable in the key hub at the shaft. The plane key has its head in shape. of circular or rectangular.

2. Saddle Key

A saddle key is a key that fits in the keyway of the hub or shaft only. In this case, there is no keyway to the shaft. It transfers the power due to friction foro which creates its own pressure. It is of two types, which are as follows.

(i) Solid Saddle Key

It is a taper key that is fitted in a keyway in the hu and is inflated on the shaft as shown in the figure. It i suchly to slip round the shaft under the load Therefore, it is used for comparatively light load.

(ii) Hollow Saddle Key

This key is rectangular-shaped, but towards the shaft side. It is circular and its radius is equal to the radius of the shaft. According to the size of the key, a keyway is made inside the hub. So, it is easily fitted into a hub or keyway. It is used for light work.

Precautions While Using the Key

Precautions while using a key are as follows:

(i)When you use the key, you must find a suitable key for work.

(ii) Keep the key away from oil, grease, etc.

(iii) The key surface is always hard, so it cannot fail

(iv) During the pulley, you must be aware of the time of enlightenment.