The file is the main hand-cutting tool of a fitter. It is made up of a hardened steel tool and has parallel rows of cutting edges on its surface. A file is a working tool, which is used to cut the fine amounts of material from a workpiece. The filing process provides the final touch of a workpiece. Some important works of a file are as follows.

(i) Chipping surface to be made smooth.

(ii) Removing undesired materials from the workpiece.

(iii) Making of die or model.

(iv) Shape up a job.

(v) Polishing of the surface.

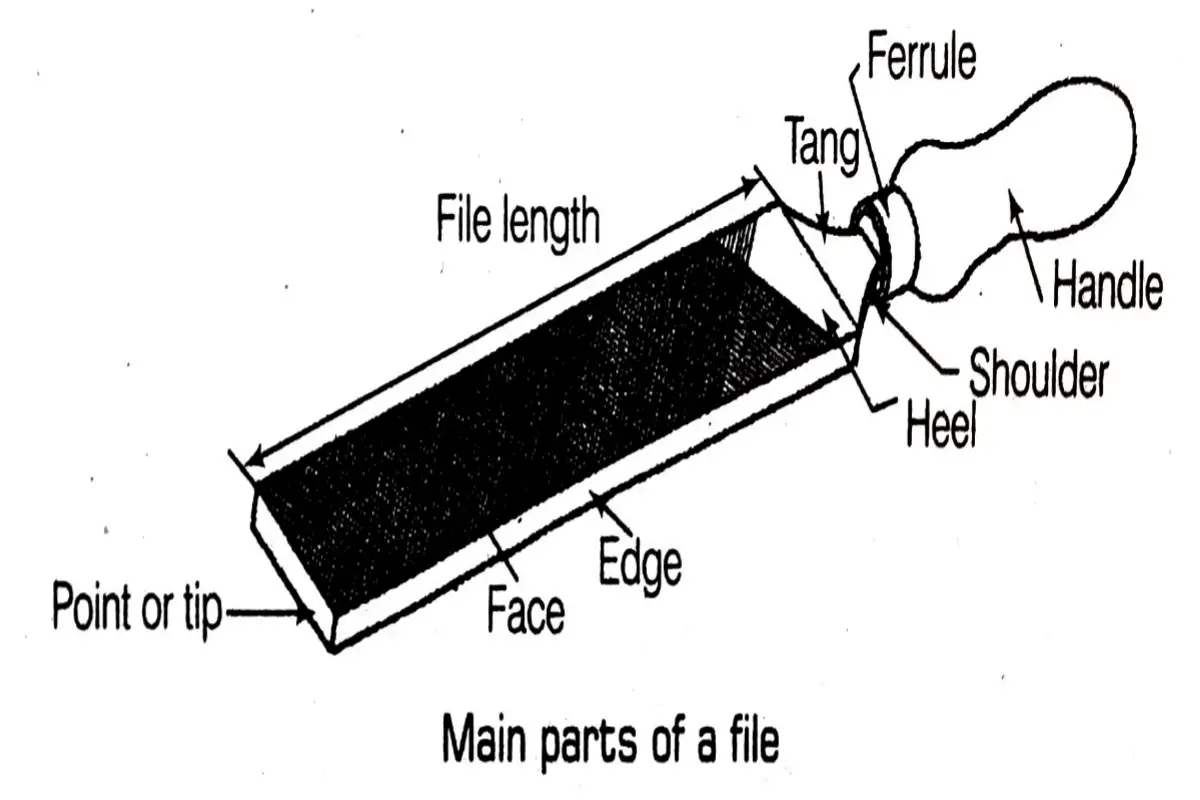

Main Parts of a File in Workshop; Fitter Theory

There are different types of files available in the market according to their work and shape or size.

(i) Face

A flat part of a file having cutting or shaping teeth is known as a face.

(ii) Tang

To make a firm grip on a file, we need a handle at the upper part of the file. The conical upper portion is called tang which is used to fit the handle on it.

(iii) Heel

The plane portion between the tang and the main body of the file is known as the heel.

(iv) Point

The bottom part of a file is known as point. This part may be triangular or plane in shape. It is also known as the tip of the file.

(v) Edge

The sides of a file are known as edges. Both sides of a file have cutting teeth, it is in work while using the file vertically.

(vi) Shoulder

The Taper part of the file is called the shoulder, which is used to mount the tang above the heel. Files are made up of forged high-carbon steel. Sometimes, tungsten steel is also used for manufacturing a file.

(vii) File Length

The size of the file length is indicated by its length, which is the distance from the point to the heel The file lengths for fine work vary from 100 to 450 mm and are weighting 50 to 150 g. For any heavy work, files are used in lengths of 250 to 450 mm.

(viii) Ferrule

It is a metal ring, that compressed the handle to hold the file tang in tightly. It is pin-uped by a very thin metal rod or nail.

(ix) Handle

It is generally made up of plastic or wood. It has a suitable shape, according to the comfort with the handling and operating efficiently. The length of the handle depends upon the length of the tang of the file.

In the workshop and domestic operations, the file is an important tool. It is widely used for finishing operations. According to its cutting edges, shapes, and grades, it is classified in the following ways

Classification/Types of Files in Workshop

According to the shape of the file, these are available in different shapes as follows.

(i) Flat File

This is a rectangular cross-section-shaped file. There is a five-time difference between its width and thickness. It has single and double cuts on both surfaces while the sides have plain teeth cut.

The length of the file is 15-40 cm in practical and available in the market for various hand-cutting purposes. It is widely used for general-purpose works.

(ii) Hand File

Hand files are used in the workshop to smooth the rough edges. It can be used to smooth, a range of materials including metals such as brass and steel. This file is made up of high-carbon steel with heat treatment. It has double-cut faces on both sides, one edge is single cut and the other edge is uncut. The uncut edge is called safe small-sized teeth as compared to others. It is used for edge. The safe edge is used for surface filing at 90°.

The file is held flat against the surface. It is used for smooth cutting. The diagram shows how the file is held during this process. The file is held in both hands by the handle and pushed forward and backward along the material. This will further smooth the material. A polishing or buffing machine can be used to polish the surface of the material. i.e. plastic and soft metal only.

(iii) Pillar File

It is very similar to the hand file with less width in thickness ratio. It is similar to a flat file due to its narrowness. These files have relatively less breadth than their thickness. The length range of pillar files is from 15 cm to 25 cm.

It is used for filing the keyways, fillets, and narrow slots:

(iv) Mill File

It has a uniform large thickness throughout the file length It has rectangular, round, or diamond-shaped edges. There are single teeth cut on both edges. These teeth are helpful in half-round groove formation. Each surface has single-cut teeth. This is used to polish the job surface at the lathe machine in general.

(v) Warding File

The warding file is very similar to the flat file, having a rectangular section and less thickness uniformly distributed over its length.

The length range is from 10 cm to 20 cm. It has a very small-sized tooth as compared to others. It is used for finishing, lightweight works, and cutting narrow slots.

(vi) Triangular File

It has an equilateral triangular cross-section shape, that consists of three rectangular surfaces with single cutting teeth. It has each edge at an angle of 60° and is used for corners. One-third part of this file is tapered towards points. It is used to double-cut at all faces of the workpiece.

(vii) Square File

It has a square cross-sectional shape that consists of four identical surfaces with double-cutting teeth at all its faces. It has one-third of the portion tapered towards the point. It is used for filling corners and slots.

(viii) Round File

It has a circular cross-sectional shape, that consists one third tapered part towards the point. It has single-cut teeth on all its surfaces. This file is used to file all the curved surfaces ie., round corners, round slots, and holes.

(ix) Half-Round File

It has a semicircular cross-sectional shape, that consists of one-third portion tapered towards the points with single-cut teeth at a side and double-cut teeth at flat surfaces. This file is used to file both curved and flat surfaces.

(x) Knife-Edge File

This file has a knife-edge shape with a cross-sectional pattern. It has a sharp edge, almost at the angle of 109°, and both surfaces have double-cut teeth. It is mainly used for filing at congested portions of the workpiece and finishing sharp corners of slots and grooves.

(xi) Needle File

The front face of the file has a needle-type structure, which is sharp and conical as well. Its normal length range is from 10 cm to 20 cm. It has a round tang and is used for light filing work, ie., tool makers, die makers, and watchmakers.

Files are classified according to the shape of teeth.

Files are classified according to the shape of the teeth list given below.

(i) Single-Cut File Use

All teeth of a single cut file are aligned in a plane uniformly and mutually parallel. These teeth lines are inclined at 60° from the center line of the surface. These files remove fewer materials but polish the surface finely. The surface made by this type of file is more smooth than double cut or any other file.

(ii) Double Cut File

In this type of file, a single cut is present as usual, but diamond-cut teeth are also mounted in reverse order and in opposite directions.

From both of the cuts, one cut is at a 60° angle from the central line, and the second cut is inclined from 75° to 80° at the center line. Due to sharp teeth, this type of file removes more materials from the workpiece and forms a rough surface. It will not give a finish but cut the particles very fast.

(iii) Rasp Cut File

In the rasp cut file, punches are in hill form raised teeth at enough distance, as such a single and double cut. This is available in flat or round shape. It is used to file wood pieces, rubber, and elastic materials.

(iv) Circular Cut File

In this type of file, cutting teeth are arranged in circular models and parallel to each other. It is used for removing less quantity of material from the soft material workpiece. It is also known as a Vixen file.

(v) Spiral Cut File

The cutting teeth of this file have a spiral model shape which starts from the point and ends at the heel. Generally, this type of cut file is obtained in a round file. It removes the thread-type grooves. It is also used for finishing work in soft metal holes.

The spacing of the teeth may be fine or coarse, depending on the required finishing. These grades apply to single-cut and double-cut files only. The grading of teeth is referred to as the thickness of cutting teeth of the files. It is measured in the number of teeth inch per square centimeter. The denseness of teeth and their shape affect their corresponding works.

Files are classified according to the grade of teeth.

(i) Rough File

It is used for rough work only to remove metal quickly. The coarse file has about 20 teeth per inch or 8 teeth per cm. It is used for both soft and hard materials. It is slipped on the surfaces of hard materials. It is used for removing rapidly a large quantity of metal.

(ii) Coarse File

Its teeth are relatively smaller in size. It has usually 10 teeth per cm. It also removes enough amount of materials.

(iii) Bastard File

It is used for common-grade ordinary engineering work. It has about 30 teeth per inch or 12 teeth per cm. It is a medium-grade file used for both soft and hard materials. This file uses the maximum number of times because of its working and functional simplicity.

(iv) Second Cut File

It is used as the common grade for a good finish quickly and has about 40 teeth per inch or 16 teeth per cm. It is widely used for finishing and cutting.

(v) Smooth File

It gives a good finish but has slow cutting. It has about 50 to 60 teeth per inch or 20 to 24 teeth per cm. It removes less materials from the job or workpiece.

(vi) Dead Smooth File

It gives a very fine finish and is used for final finishing only. It has about 100 teeth per inch or 28 to 35 teeth per cm. It also removes less materials. It is frequently used for fine finishing and accurate size.

(vii) Super Dead Smooth File

It has less length as compared to the other files. It has about 40 to 65 teeth per cm. It is used to obtain an accurate finishing surface according to the requirement.

Some other types of files which are used to perform special work which can not be done by a general file are discussed below.

(i) Rat Tail File

This file is similar to the round file. It has less radius with tapered in length.

It looks like the tail of a rat. Its length is from 10 to 15 cm long. It is used to file a small hole.

(ii) Flexible File

It is thicker than a hacksaw blade but enough flexible with two holes at the ends. These holes are helped to handle the grip. This is used to fill the curve surfaces.

(iii) Rotary File

These files are used in machines while held by hand. It is used in a lathe machine or drill machine with the help of a spindle. These files are made up of high-speed steel or cemented carbide. It is used to increase the cavity of a die.

(iv) Crossing File

This file has flat surfaces both surfaces have different radii. This file is used to file the curved surface.

(v) Barret File

It has a triangular shape with a cross-section area. One surface is wider than the rest of the two. The wider surface contains the cut teeth only. It is used to file a job of having a 60° inclination at the edge. It is also known as a Cantt file.

(vi) Feather File

It is designed to have sharper rip-cut blades. It is used only on the rip-cut edge of the blade. It is mostly recommended for cross-cut filling. This file has a 100 mm size for sharping larger Ryoba saw teeth.

(vii) Crochet File

It is similar to a flat file and has a flat surface, but both edges have a round shape. Single-cut teeth are mounted on it, which are used to make circular grooves. This file is also known as a mil file.

(viii) Die Sinker’s File

These files are used for specific molding or cutting die-making fitters. These are available in different grades with sets of 12 having lengths of 10 cm.

(ix) Die Sinker’s Refflers

These are also used for die-making. It has two-sided files around the handle. One set has 18 files.

(x) Band File

Every block of this file is fixed on the steel belt of the band machine with the help of screws or rivets. While motioning of steel belt, pressurize the all workpieces due to the opposite pressure and start the filing.

(xi) Block File

These files are rectangular and have cutting teeth on only one side. Handles are fitted on the upper surface, so are used to fill a large area of the flat surface.

Apart from all these discussed so far, files can also be classified according to their length. The length of a file consists of the total distance between the point and the heel.

There is an availability of files, which have a length range of 10 to 45 cm. These types of files are used according to finishing and fine work on the surface of the job. For light work jobs, lengths of 10 to 15 cm files are used. Medium work job is done with the help of a 15 to 25-cm file.

Uses of Files in a Workshop

Files are versatile tools used in various applications within a workshop. Here, we’ll describe how files are utilized in metalworking, woodworking, and working with plastic and other materials.

Metalworking

- Smoothing Rough Edges

- Description: After cutting or machining metal, the edges can be sharp and uneven. Files are used to smooth these rough edges, making the metal safer to handle and providing a more finished appearance.

- Tool: Flat files or half-round files are commonly used for this purpose.

- Shaping Metal Components

- Description: Files can be used to shape metal parts to precise dimensions or to create specific forms. This is especially useful in custom fabrication and fine-tuning metal pieces.

- Tool: Various files, including round, triangular, and square files, can be selected based on the shape required.

- Sharpening Tools

- Description: Metal files are excellent for sharpening the edges of tools such as saws, chisels, and blades. By filing along the edge, you can restore the sharpness and effectiveness of the tool.

- Tool: Mill files and triangular files are typically used for sharpening purposes.

Woodworking

- Removing Excess Material

- Description: When working with wood, excess material often needs to be removed to achieve the desired shape. Files are used to gradually remove wood, allowing for precise control.

- Tool: Rasps and half-round files are commonly used for this task due to their ability to remove material quickly.

- Shaping Wooden Pieces

- Description: Files are used to shape wooden components, creating curves, angles, and intricate details. This is essential in custom woodworking and furniture making.

- Tool: Half-round, round, and flat files are frequently used, depending on the shape required.

- Smoothing Surfaces Before Sanding

- Description: Before sanding, files are used to smooth out rough surfaces and remove larger imperfections. This prepares the wood for a finer finish with sandpaper.

- Tool: Flat files and rasps are often used for initial smoothing.

Plastic and Other Materials

- Trimming and Shaping Plastic Components

- Description: Files are used to trim and shape plastic parts, especially after cutting or molding. They help achieve precise dimensions and smooth edges.

- Tool: Flat files, needle files, and round files are useful for working with plastic.

- Smoothing Edges of Synthetic Materials

- Description: Synthetic materials like fiberglass, acrylic, and composites often need their edges smoothed after cutting. Files are effective in removing rough spots and creating a polished edge.

- Tool: Various files, including flat and half-round files, can be used depending on the material and the desired finish.

What is a Filing workshop?

Filing is the process of the removal of undesired extra material from the workpiece. It is functionally versatile but is used mostly for finishing operations. Small jobs or workpieces are gripped within a bench vice, which holds the workpiece and stops the movement of the workpiece during filing. In the case of heavy jobs no requirement to fix the workpiece because of its heavy weight.

Procedure of Filing

For proper filing, the following steps are to be followed.

Step I

Right marking on a given job.

Step II

Fix the job in the bench vice, according to the shape and size, the job should be at least 3 mm to 8 mm outside of the vice grip.

Step III

Select the files according to the size and shape of the workpiece.

Step IV

Stand in front of the vice towards the job filing direction. The left leg should be leading by 30 cm from another one.

Step V

Grip the handle in the right hand to create pressure on the surface of the workpiece. The left hand is used to balance the working system.

Step VI

File the surface from one end to another end to yield a plane surface, using the full length of life.

Step VII

In the forward motion of the file, pressure should be maintained to cut down the extra materials while returning motion should be normal.

Step VIII

Try square is used to check the flatness of the surface.

Step IX

Full-length utility of the file finishes the work early.

Step X

Pining of the file should be done from time to time.

Ways of Filing

According to the operation, there are many ways of filing which are as follows.

(i) Straight Filing

For normal flat filing, the operator should aim to carry the file in the forward direction on an almost straight line in the same plane, changing its course enough to prevent grooving. Too much pressure is provided which often results in a rocking motion causing a rounded surface.

(ii) Cross Filing

This type of filing is done at 45° cross inclination to the plane or axis of the vice. The possibility of chattering is less and the flatness of the surfaces is improved because of having a cross-filing direction. It is widely used for wide surfaces. It is also called diagonal filing.

(iii) Draw Filing

Draw filing consists of grasping the file firmly at each end and alternatively, pushing to pull across the work. Since files are made primarily to cut on a longitudinal forward stroke.

(iv) Curved Filing

This is used to fill the curved surfaces, handle moves around the edge from one end to another end in forward stroke motion.

Precautions While Filing

(i) One should always use a file card to clean the file. Never use your hand. The chips may penetrate in hand and cause a painful infection.

(ii) One should not use a file without a handle.

(iii) Short burns formed in filling may cause serious cuts. Always use a piece of cloth to wipe the surface being filed.

(iv) Files are highly brittle and should never be used as a hammer otherwise the file will break.

(v) Grease or oil should not be used on the workpiece during filing.

What is the double-cut file?

A double-cut file has two rows of teeth cut diagonal to each other. The first row of teeth is known as over-cut with an angle of 70 degrees. The other cut is made in a diagonal is known as an up cut with an angle of 50 degrees.

What is a filing process?

A filing process refers to the systematic and organized method of arranging and storing documents or information in a structured manner. This process is crucial for efficient data management and retrieval. The key steps in a filing process typically include:

Sorting: Organizing documents based on their type, category, or relevance.

Indexing: Assigning identifiers or labels to documents to facilitate easy retrieval.

Categorization: Placing documents into designated folders or sections based on their content.

Labeling: Mark folders or containers with information about their contents.

Storage: Placing the organized documents in a designated physical or digital location.

Maintenance: Regularly reviewing and updating the filing system to accommodate new documents and ensure continued relevance.

Effective filing processes help streamline workflow, reduce the time spent searching for information, and contribute to overall organizational efficiency. In a digital context, filing processes can also involve the use of document management systems and software for seamless organization and retrieval of electronic files.

What is filling in engineering?

It seems like there might be a small typo in your question. If you meant “filing” in engineering, it typically refers to the process of smoothing or shaping a material, often metal, using a file. A file is a tool with a roughened surface that is used to remove small amounts of material, creating a smoother or more precise shape in the workpiece. Filing is a common manual machining operation in various engineering and metalworking applications.

What is a workshop file?

A workshop file is a hand tool used in metalworking and woodworking for shaping, smoothing, and removing material from a workpiece. It typically consists of a hardened steel bar with a series of parallel ridges or teeth, called the file’s cut, along its surface. Workshop files come in various shapes and sizes, each designed for specific tasks such as shaping, deburring, or finishing. They are essential tools in manufacturing and maintenance processes, allowing workers to achieve precise dimensions and smooth surfaces in their projects.

What is the file in tools?

In the context of tools, a “file” refers to a hand tool used for shaping, smoothing, or removing material from a workpiece. Files typically consist of a hardened steel bar with a pattern of parallel ridges or teeth on one or both surfaces, known as the file’s cut. They come in various shapes and sizes, each designed for specific tasks in metalworking, woodworking, or other related applications. Files are crucial for achieving precise dimensions and creating smooth surfaces in a variety of manual machining and finishing processes.