A hammer is an important tool in a workshop, meant to deliver an impact to an object. The most common uses of hammers are to drive nails, forging, bending rivetting, chipping, bunching, straightening, etc. Hammers are often designed for a specific purpose and vary in shape and structure.

A 🔨 is a fundamental tool in many professions. It is made up of carbon steel. The usual features of a 🔨 are a handle and a head with the most weight in the head. The basic design is hand-operated, but there are also many mechanically operated models such as steam hammers for heavier uses.

The following types of hammers are generally used.

1. Hand Hammer

It is made up of carbon steel or cast steel. Its face and peen are hard and tempered. Its central part is known as the post. The post is soft i.e., the is has some flexibility and has an eye-hole shape such ellipse. This hole is used for the handle. The handle is fitted in tight duty by riveting.

Based on the peen, hammers are of different types as given below.

(i) Ball Peen Hammer

It is normally used for shaping metal and closing rivets. The peen, in this type of, is rounded. It has a ball-type peen and a flat face. Ball peen hammers are available in 110 to 165 g.

These are the most suitable for general use. Handles are normally made of wood. It is widely used in marking, chipping, and reverting.

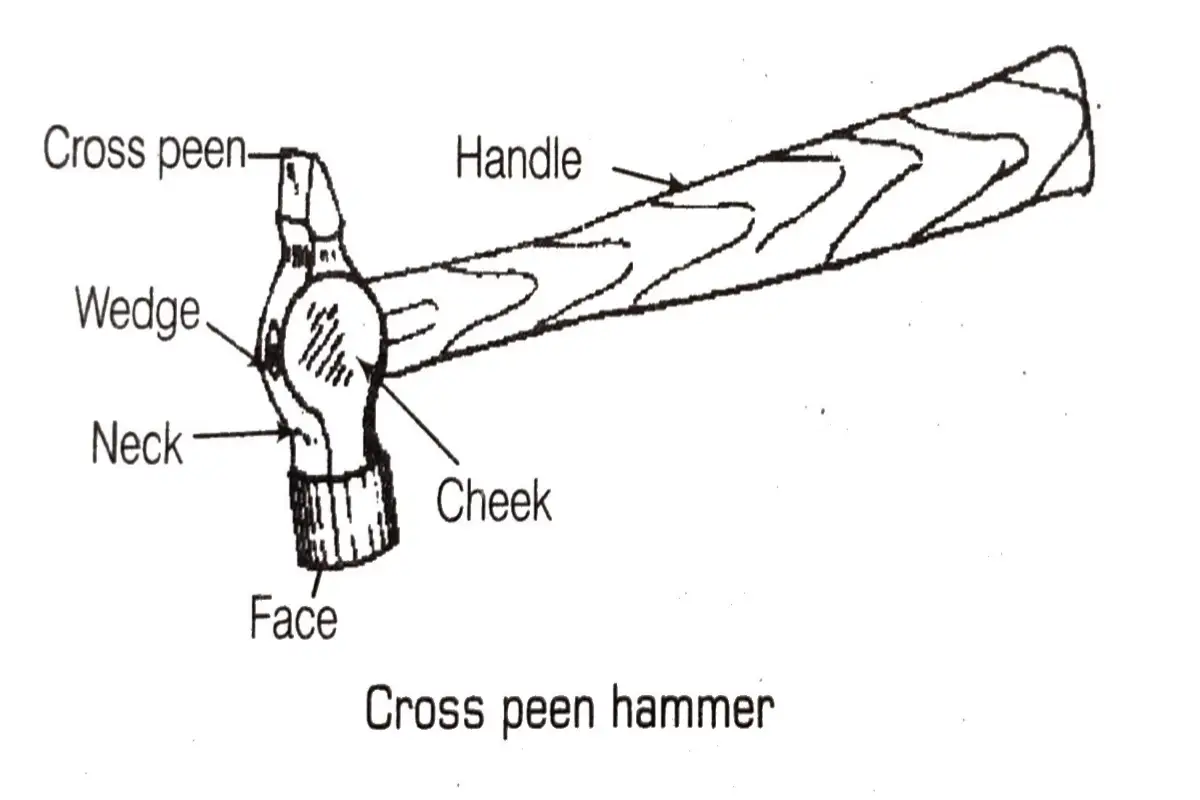

(ii) Cross Peen Hammer

This is mostly used for making pipes, V-grooves, inside-edge jobs, revert head faltering, etc. It is been is standing at a right angle from its handle, but has a cross peen from the handle. It has a piled peen i.e., cross the.

(iii) Straight Peen Hammer

It is peen is parallel to the handle. It is mostly used in smithy shops for swaging, grooving, and riveting. Its sizes vary from 0.12 to 10 kg.

(iv) Double Face Hammer

This type of has a double end and is used to hit a on job both sides. It is widely used in the riveting process for hitting the cup tool.

(v) Claw Hammer

This is the most popular which is used in carpentry shops. It is made up of cast iron. Its claw face is flat, but its claw is normally curved, which has a V-shape such as a cutting shape. This edge is used to remove the nails from the wood.

(vi) Soft Hammer

Made up of brass, copper, lead, aluminum, wood, hard rubber, bakelite, and nylon. It is an important tool for sheet metal shops. It is used to seat work in a machine vice to drive a mandrel etc. It is used in bearing and assembling.

Types of soft hammer

Soft hammers are further classified as

(i) Raw Hide 🔨

This is similar to a double-face and has a leather cover on both faces. It is used to maintain accuracy and finishing of the jobs.

(ii) Mallet 🔨

It is used to light strike on metal for bending and winding. It is made up of hardwood or hard rubber. eg., Teak, shisam, kiker, etc.

(iii) Nylon 🔨

This is made up of steel and hard plastic fixed on both sides. It is used for parts assembling such as furnishing. In this, hammering has no marks on the job after strikes. eg, Tool room, aeronautic shop, etc.

(iv) Plastic 🔨

It is made up of steel same as nylon. Both ends are covered by a ‘plastic pad or rubber pad for the well furnishing. It is used for light-duty hitting.

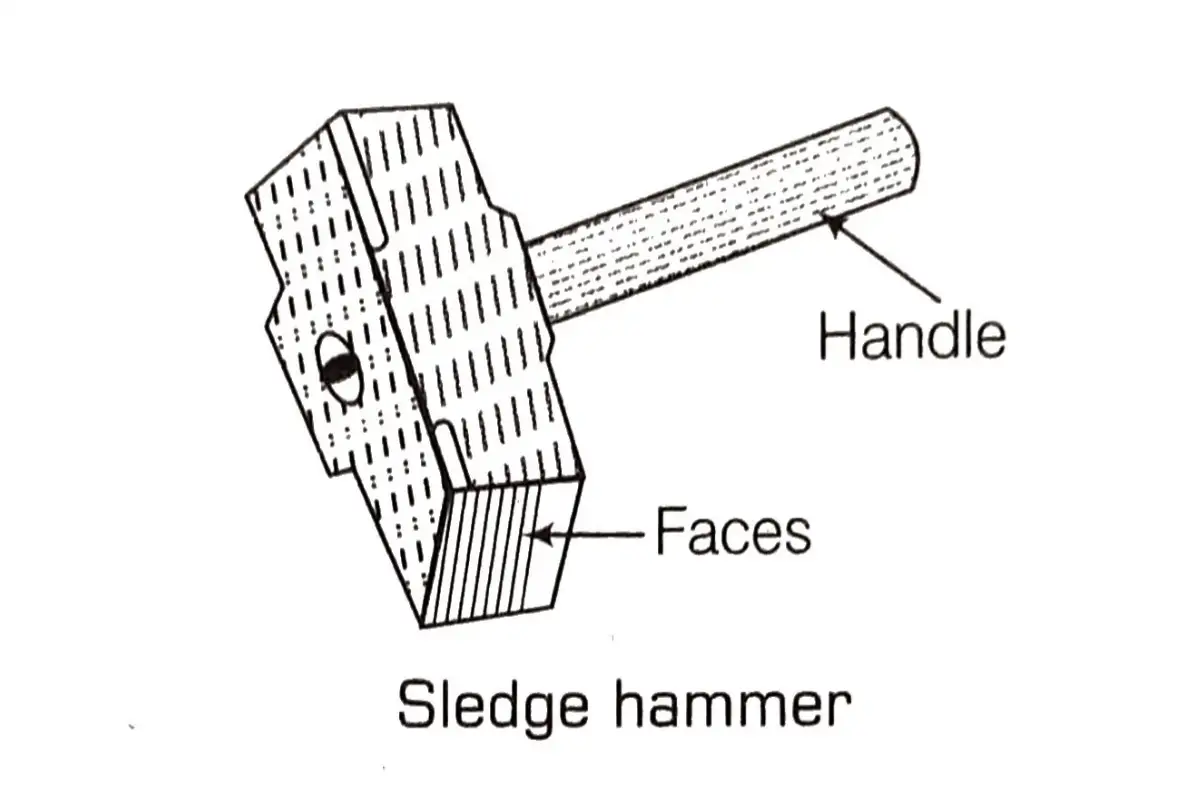

2. Sledge Hammer

A sledge is used for cutting an iron angle, rod, etc., by using cutting dies, forging, heavy hitting, etc. It is heavy as compared to others and its weight varies from 2 to 10 kg. It has a flat surface on both sides.

Precautions While Using 🔨

Precautions while using a 🔨 are as follows.

(1) Always select a suitable according to your job.

(ii) Check the looseness of your handle, if it is loose then you tight-toned it.

(iii) Always use the proper way to hit the job.

(iv) Never use a surface that has an oiler or grease.

(v) Always wear safety glasses when driving nails are breaking up the concrete.

Share great information about your blog , Blog really helpful for us .

“Thank you so much for your kind words! I’m thrilled to hear that you find my blog helpful. I appreciate your support and hope to continue providing valuable content for you. Happy reading!”