A plier is a hand tool having two legs joined by the pivot. Each leg consists of a long handle and a short jaw. It is classified by the shape of the mouth and overall length. The overall length varies from 150 to 230 mm. It is generally made of cast steel and very useful in pliers’ workshops to catch the job cutting or bending of wires, etc.

Types of Pliers & Their Uses

According to its shape and working, there are the following types of pliers.

(i) Side Cutting Plier or Combination Plier

The side cutting plier has two jaws cutting edges to cut soft wires. This is used by mostly line man or wire man. It is available with an insulated cover on its legs known as an insulated cover which protects from electric current. This is also used in workshops to grip different objects.

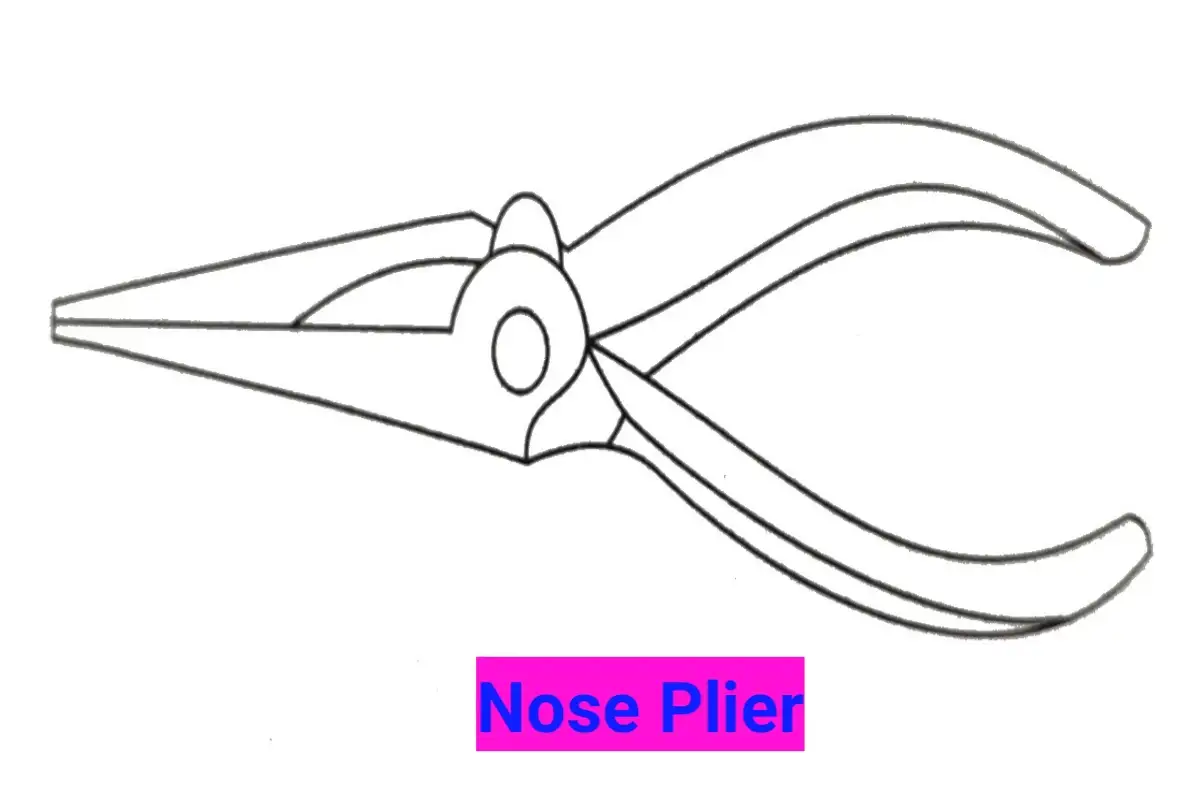

(ii) Nose Plier

It consists of tapered-edge jaws, which jaw is sharp and long. It is used to grip the components and tightened them in a narrow place. The backsides of the jaw have side-cutting edges, which are similar to the side-cutting plier and are mostly used by wiremen

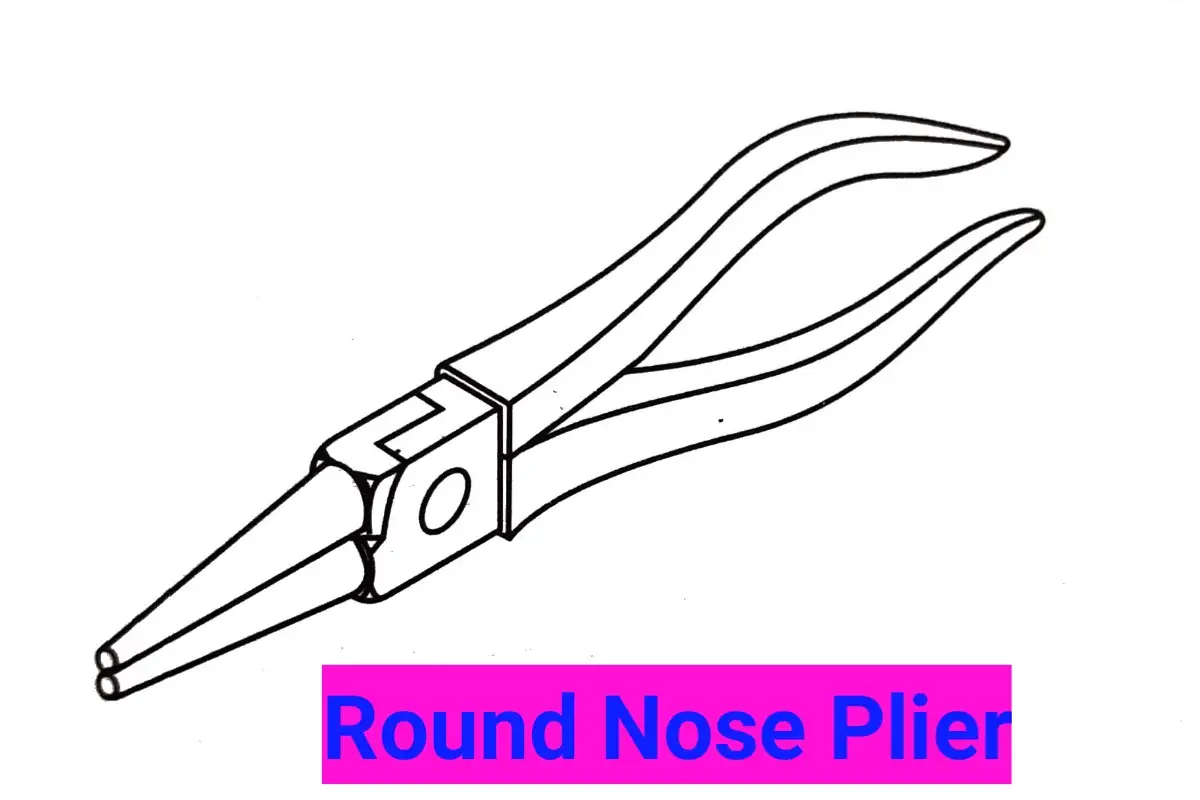

(a) Round Nose Pliers

It consists of tapered round-shaped jaws which are generally used to shape loops in wires and to form curves in light metal strips. This type of plier is generally used by electricians and radio mechanics.

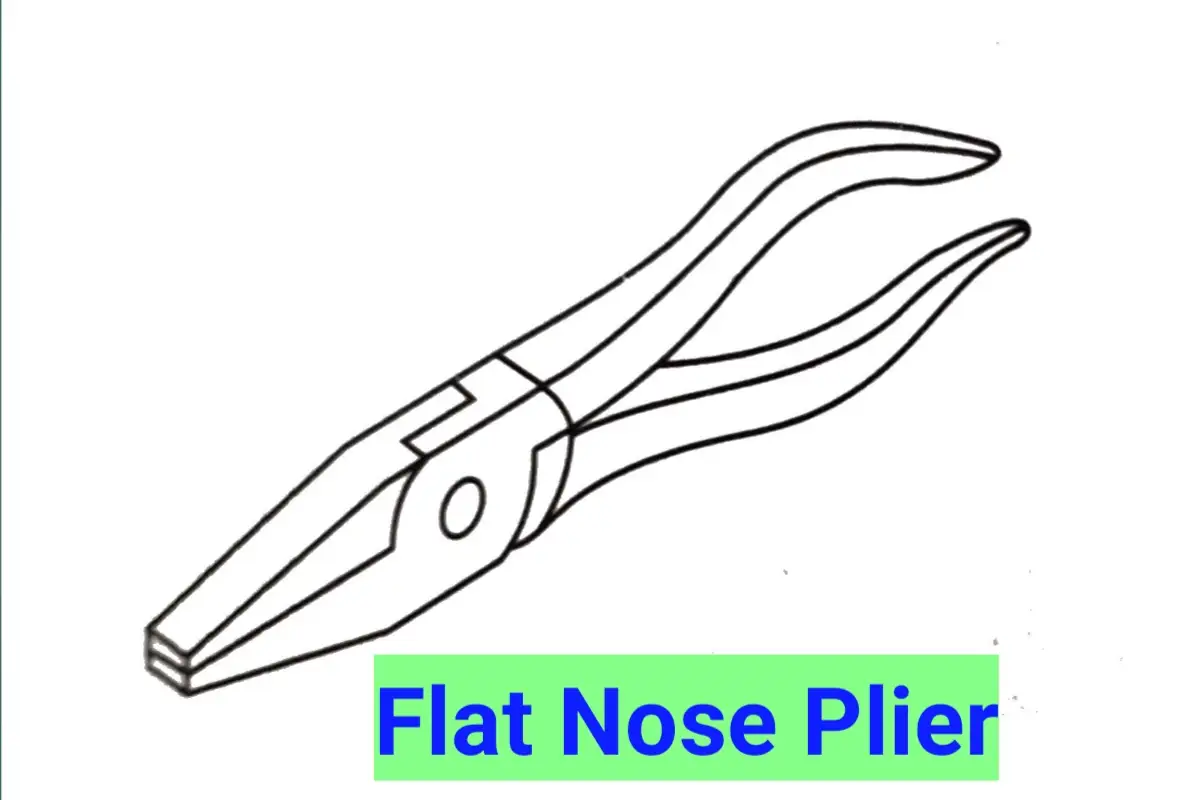

(b) Flat Nose Pliers

It consists of tapered wedge jaws with flat gripping surfaces (either smooth or serrated). It is used for bending and folding narrow strips of thin sheet metal.

(iii) Diagonal or Wire Cutter Plier

It is used to grip round square, flat and hexagonal objects. It can apply limited torque i.e., twisting force, without damaging the work. It does not have gripping jaws. It is mostly used in electrical, radio, or instrument sections.

(iv) Slip Joint Plier

It is generally used for gripping purposes. In this plier, make up a slip joint to use a lever at two places so that, plier efficiency is increased for gripping and easily gripping the wide objects. Its backward parts have cutting edges hence, it is used to cut wire.

(v) Multi Grip Plier

As its name, it is used for many purposes for the job and adjusted into any size such as 0 to 50 mm, and carries 5 or 7 joints. These pliers are provided a range of jaw openings and allow parallel gripping by jaws in a number of positions.

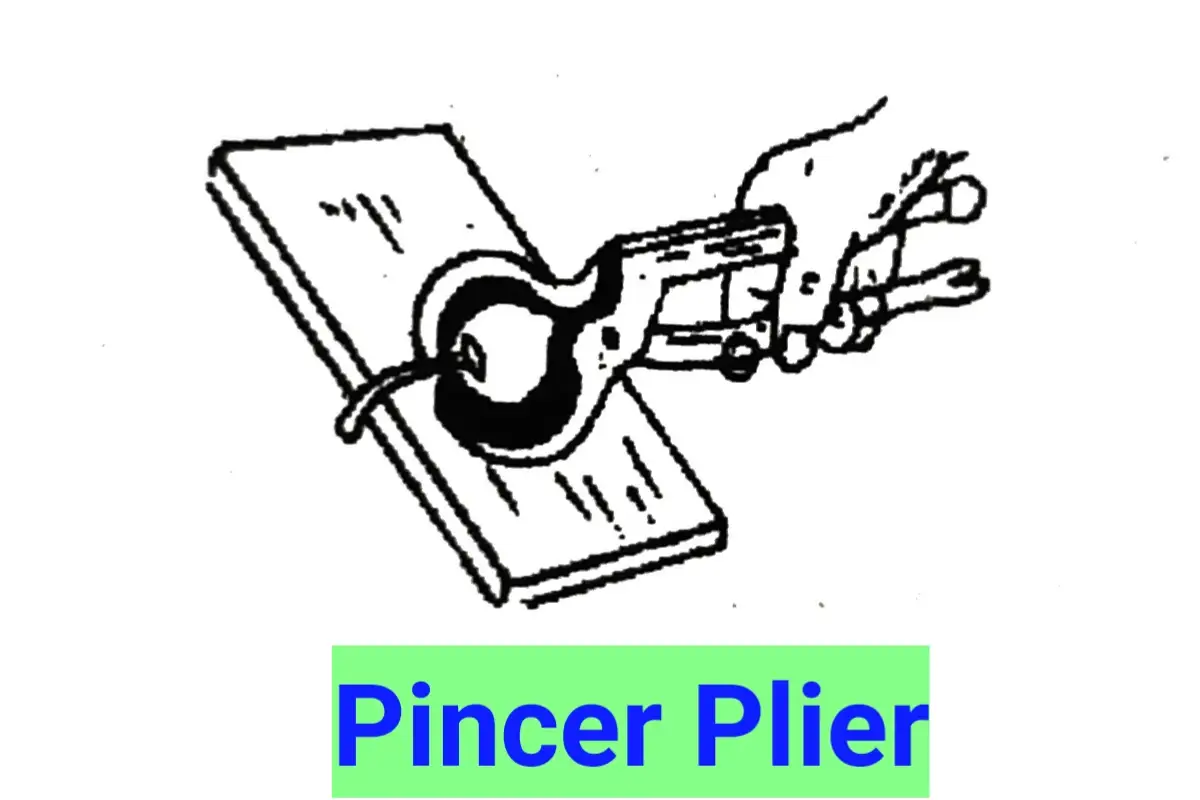

(vi) Pincer Plier

This plier is used to remove the nails from plywood and its jaw has a circular and sharp shape so that, it is easy to catch the nails.

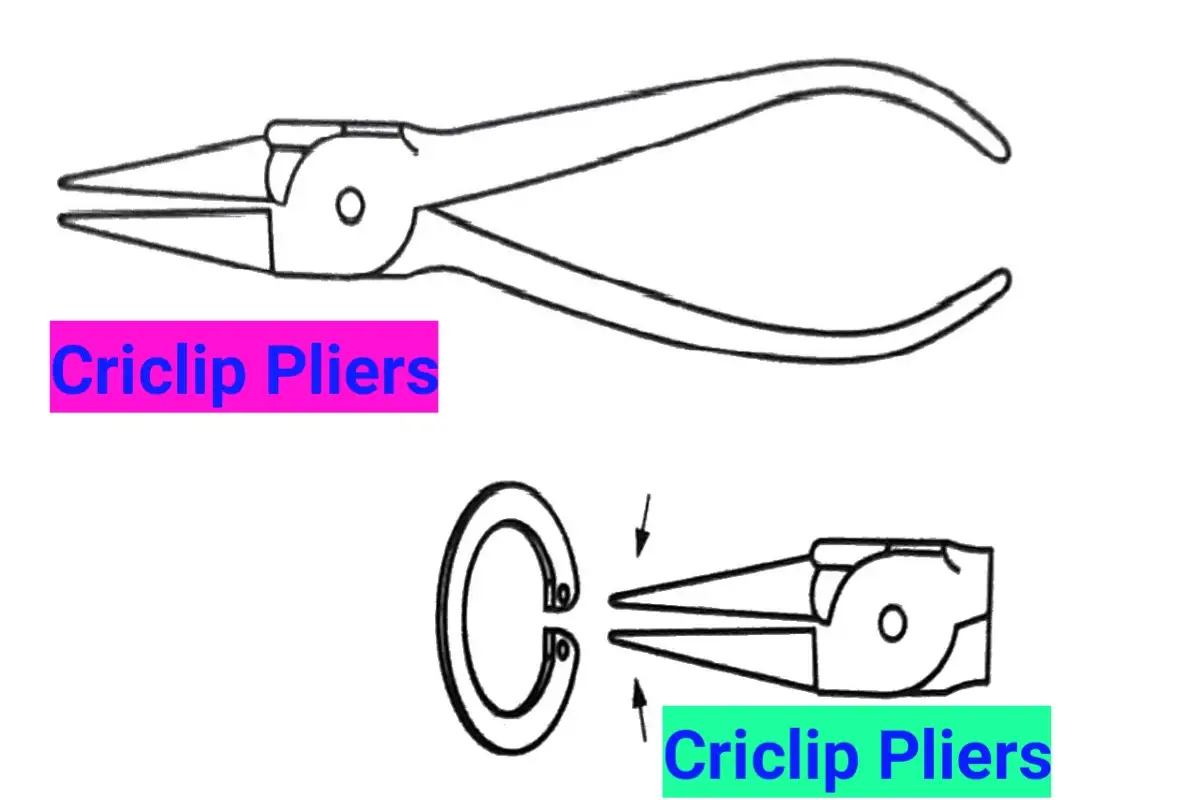

(vii)Circlip Pliers

These pliers are used for fitting and removing the circlips in assembly works. For this purpose, external and internal circlip pliers are used. Internal circlip plier.

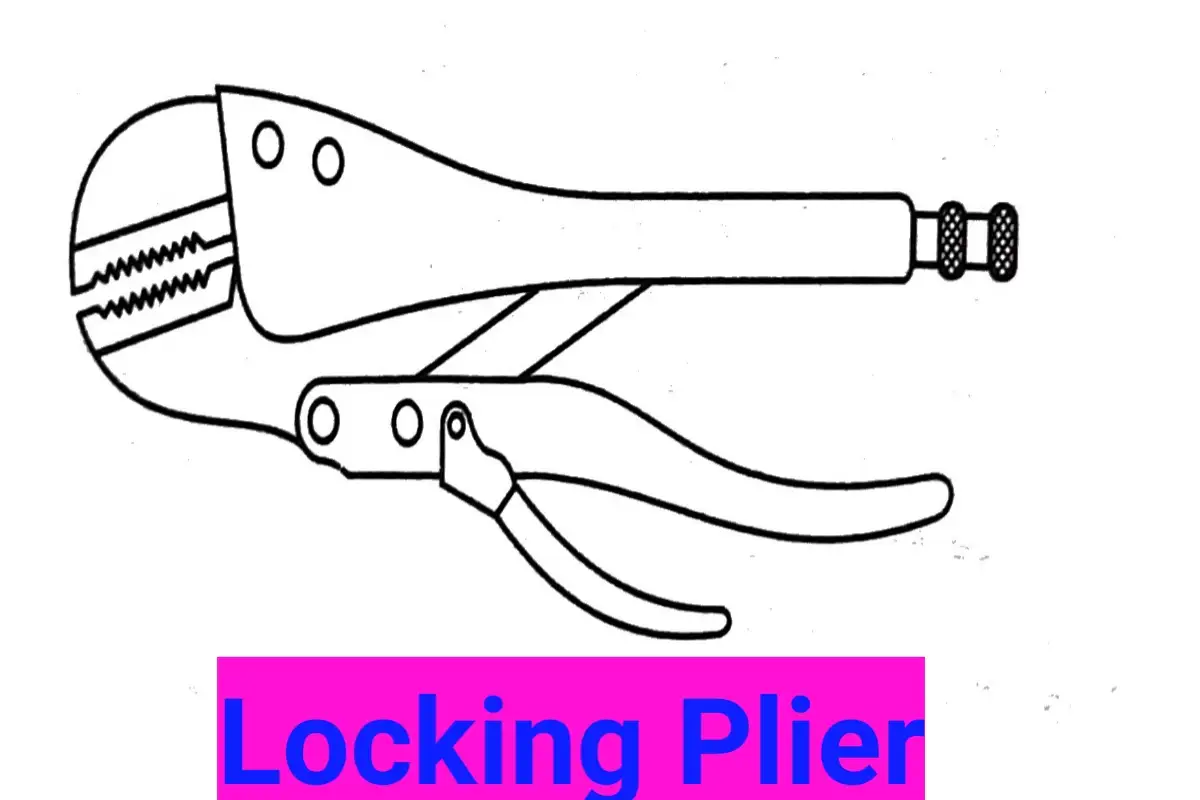

(viii) Locking Pliers

A locking lever is attached to these pliers to clamp the jaws onto a job of any shape. These pliers are generally used where locking is necessary after gripping a job.

Care and Maintenance of Pliers

- Rinse after use.

- Coat with light oil when not in use.

- Store in a toolbox in such a manner that jaws cannot be injured by striking hard objects. Remove rust spots with fine steel wool or a wire brush.

- Periodically wipe down the pliers with a lubricant.

- Check and tighten jaw and cutter screws.

- Keep Cutters sharp.

When the serrations of pliers’ jaws become damaged or worn, or when the cutting edges become dulled or nicked, they must be repaired. The jaw serrations must be either ground on a V-shaped wheel or filed with a V-shaped or triangular-shaped file.

Precautions While Using Plier

(i) You must be conscious when you use it.

(ii) Select suitable tools according to your job.

(iii) Always use tools with appropriate pressure.