Punches are used to make certain dimensional features of the layout permanent. It is made up of high-carbon steel or tool steel and its point is hard and tempered. Its body is such as an octagon (eight sides) or round in shape with knurling over it. It has three parts such as head, body, and point.

Types of Punch and Angle

There are many types of punches and angles listed below.

(i) Dot Punch Drawing

It is molded of cast steel and its pointer has a 60ο angle... A dot punch is used to make a witness mark for the permanent marking.

(ii) Centre Punch Angle

The angle of the point is 90ο in a center punch. It is used to locate the center of holes in wide and deep shapes. Its center portion of the body is knurled. It is also used for drilling centers…

(iii) Prick Punch

The angle of the prick punch is 30ο or 60ο. The 30ο point is used for marking light marks and drawing a curve. It is used for soft metals such as brass, copper, aluminum, etc. The 60ο prick punch is used for marking witness marks.

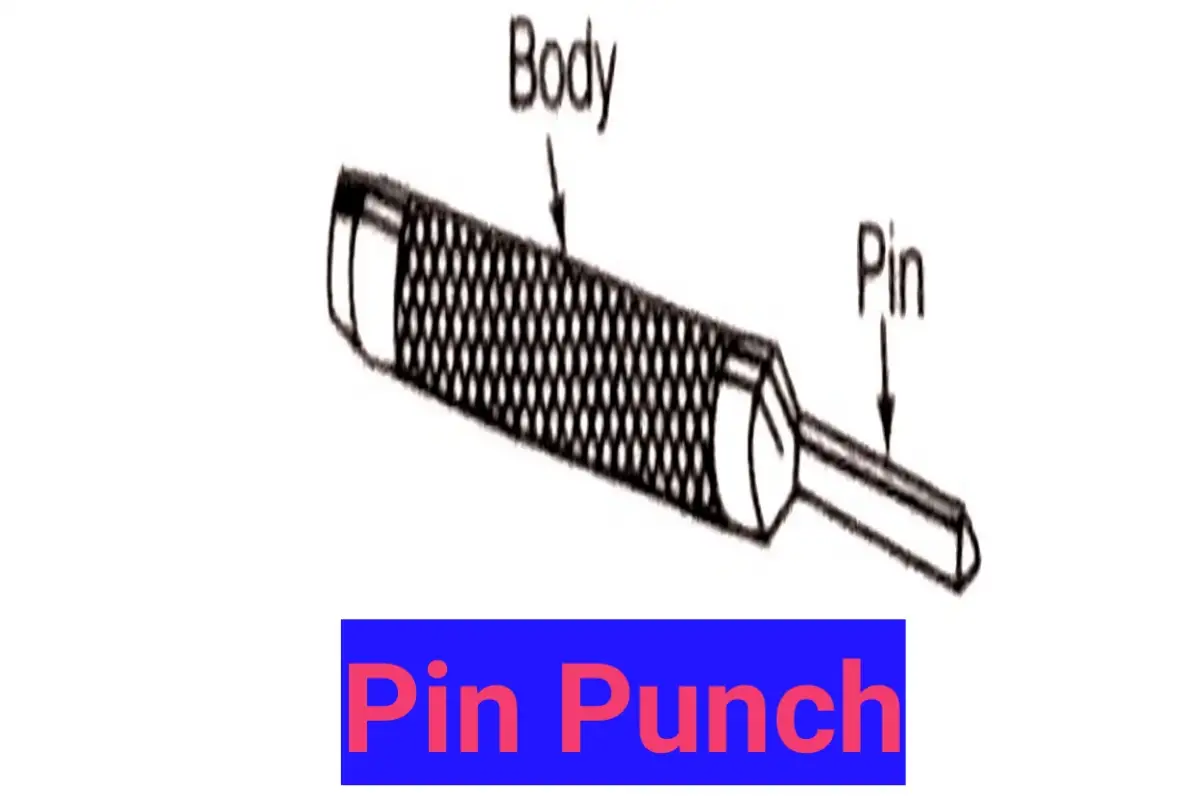

(iv) Pin Punch

It is longer and parallel in shape and is used to draw out the pin. It is not pointed but has a cylindrical pin.

(v) Drift Punch

The point of punch is of different sizes such as square, rectangular, and circular. Its end is not pointed but flat and used to hole in a thin layer.

(vi) Bell Punch

This is used to find out the center or mark on a round rod. Its front portion is like a bell and its size depends upon the circumference of the rod. A punch is attached to its center, which is pushed by a spring as shown in the figure.

(vii) Automatic Punch

It is a modern punch and while using it, there is no need to strike a hammer over a punch head. It is used for fine and accurate marking. It has a spring and steel block setting i.e. whenever we put pressure on the punch. It started marking without hammering. The quantity of strike (pressure) can be adjusted by p rotating its cap fitted to the back. Its cutting point is either 60ο or 90ο.

(viii) Hollow Punch

It is used to make holes in soft sheets such as board, leather, gas cut sheets, flat bells, soft metal, non-ferrous metal, thin iron sheets, etc. It is hollow from the inside and available in different sizes as per hole.

(ix) Solid Punch

It is used to make holes in the sheet and these holes are not accurate in size so, it is used for rough work. While doing a hole in the sheet, a nut is placed below the sheet It is used in sheet metal and blacksmith-related work as follows.

Difference between Centre and Dot Punches

| Centre Punch | Dot Punch |

| It has a 90ο angle. | It has a 60ο angle. |

| It is used to have a deep mark on the center. | It is used to make permanent marks on outer lines. |

| It is made up of high carbon steel with the front portion hard and tempered. | It is also made up of high carbon steel with the front portion hard and tempered. |

| Its length is 100 to 150 mm and its diameter is 6 to 13 mm. | Its length is 100 to 150 mm and its diameter is 6 to 13 mm. |

Parallel Block

It has a rectangular shape with different lengths and breadth of steel block which is hard, tempered, and ground. Its length and breadth sides are parallel to each other. It is used for job setting in machining. Parallel blocks are available in different types of pairs, which are used according to the need.

2 Types of Parallel Block

In general two types of parallel blocks

(i) Solid Parallel Block

These are mostly used in machine workshops. It is available in a set of two, having the same length, breadth, and height. These are available in two grades namely A and B. A grade is used in a tool room and a B grade in a machine shop.

(ii) Adjustable Parallel Block

Two tapered blocks slide on each other. One block has a cut groove and a second tongue. These are adjusted parallelwise for different height settings. It is used for setting parallel jobs during machining on the vice table to give support or lift upward.

Safety Precautions for Layout Work

Proper safety must always be practiced when performing layout work. Layout tools are sharp objects and require careful handling. Large pieces of metal stock and other materials can pose hazards and must be handled safely.

The following precautions should be observed when laying out a job.

(i) Never carry an open scriber, divider, or trammel hermaphrodite caliper in your pocket. or

(ii) Always cover all sharp tool points with a cork when the tool is not in use. When laying out work, place tools on the bench with the points facing away from you.

(iii) Avoid handing a sharp tool to another person with the pointed end sticking out.

(iv) Always wear goggles, when grinding the points of a scriber.

(v) Get help, if you have to move heavy angle plates, large V-blocks, or other large equipment.

(vi) Remove all burrs and sharp edges from the stock before starting the layout