- Introduction

- Tool Maker Vice Diagram

- What is Vice

- Precautions While Using Vice

- 1. What are the different types of vices commonly used in workshops?

- 2. What are some common hand tools found in a workshop?

- 3. What are the main types of keys used in workshops?

- 4. How do I choose the right vice for my workshop needs?

- 5. What are the safety precautions to keep in mind when using vices in a workshop?

- 6. What are some essential maintenance tips for hand tools?

- 7. How do I prevent keys from getting lost in the workshop?

- 8. Can vices be used for woodworking projects?

- 9. What are the advantages of using different types of keys for different tasks?

- 10. Are there any specialized vices for holding irregularly shaped workpieces?

Introduction

Hand tools are essential for some operations in a workshop. Operations such as sawing, filing, polishing, chipping, tapping, and threading must be mastered by a fitter. Skill in the use of hand tools can only be acquired through patience and practice; there is no easy way. Hand tools must be used with due care. This will keep tools in safe and good working condition.

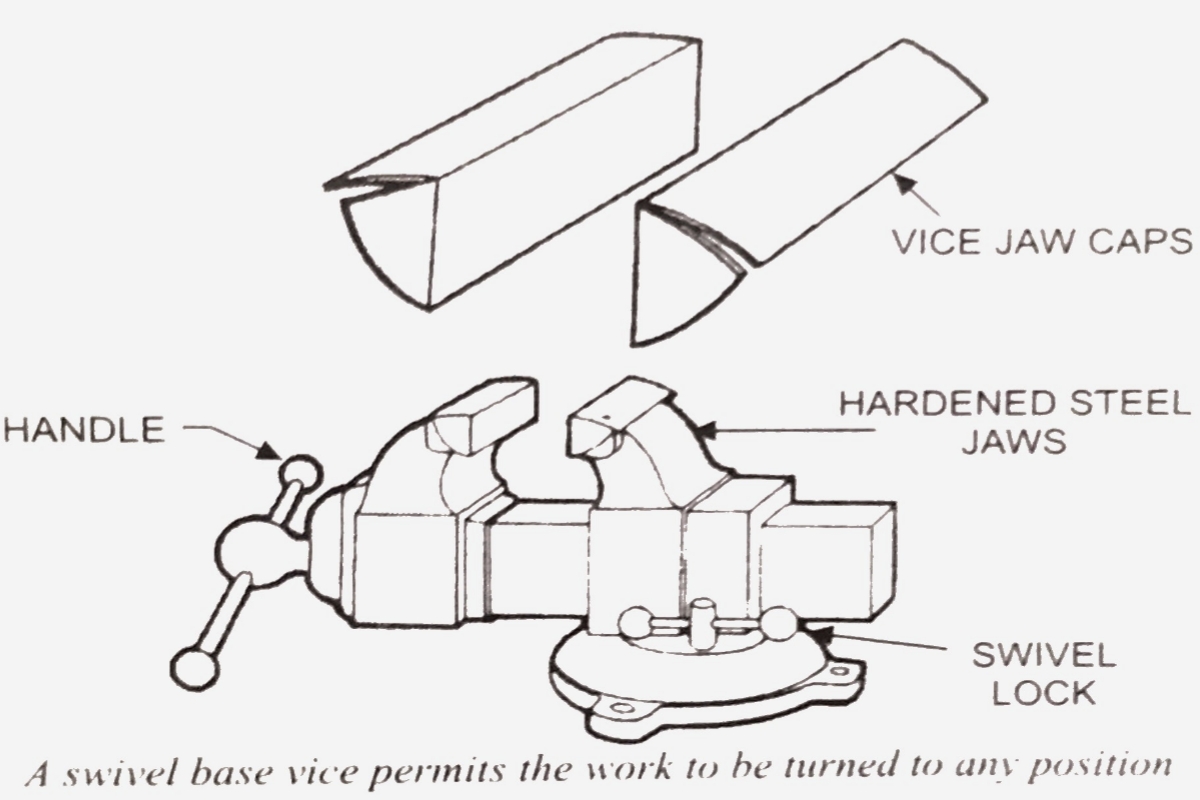

Tool Maker Vice Diagram

A tool is a physical item that can be used to achieve a goal and aids in the performance of any operation. The hand tools allow you to project or complete a job easily. In a craftsman/fitter workshop, to perform a particular job or work, some different types of hand tools are needed such as vices, hammers, spanners, screwdrivers, wrenches, etc. Some more hand tools are used for cutting purposes such as hacksaws, chisels, drills, reams, dies, files, etc. A craftsman uses hand tools with his skill and the requirements of the job. Hand tools are the important parts of the workshop. In this chapter, we will discuss some widely used hand tools and keys.

What is Vice

The device which is used to hold the job is called a vice. Generally, it is made up of cast iron. The vices are used for filling, milling, and other machining processes. These are also used in workshops to do the work with accuracy and ease. Vice has jaws, which are used to tighten the job. To grip the job properly, the teeth are cut on their jaws. Sometimes, jaws are marked on the job surface when holding to the job so in this case, we can use the soft jaw, made of aluminum plate. From the width of the jaw, we can measure the size of the vice, which is available in different shapes.

Types of Vice

According to the works and shapes, the vices have the following types as below.

(i) Bench Vice

It is firmly fixed to the bench with the help of nuts and bolts. It consists of a cast iron body and cast iron jaws. Two jaw plates are fitted on both jaws.

The holding surfaces of the jaw plates are knurled to increase the gripping. One jaw is fixed to the body and the second jaw is movable with the help of a handle. Both jaws have tapered shapes with reads in initially, to the tightly gripping of the workpiece. The jaws are opened up to the required length. The job is placed between the jaw plates and fully tightened with the help of a handle. The handle is used for rotating the movable jaw.

It is widely used in the workshop to perform the required operations. Due to the requirements of the job work, we can use the many types of bench vices.

Parts of Bench Vice and Material

| Sl. No | Parts | Material |

| 1 | Fixed jaw | Grey cast iron |

| 2 | Movable jaw | Grey cast iron |

| 3 | Jaw plates | Tool steel |

| 4 | Spindle | Mild steel |

| 5 | Handle | Mild steel |

| 6 | Box nut | Cast iron, Phosphorous |

Points to be Noted While Fixing a Bench Vice

- The height of the vice should be approximately 1 meter from the shop floor to the top of the vice or it should be equal to the worker’s elbow height.

- The bench vice should be preferably fixed over a leg of the bench for better support and stability with proper bolts, nuts, and washers.

- It should be level and the vice jaws must be parallel to the workbench and shop floor. If it is not fixed in level, the material will be removed more from one of the sides.

- Its fixed jaw should be protruding a little beyond the edge of the workbench to hold the lengthy workpiece vertically.

- The vice should be fixed rigidly. If it is not fixed rigidly, it will vibrate and impair the surface finish and accuracy.

Adjustment of Bench Vice Height

- The height is correct if the worker’s fingers touch his chin with the elbow put on the top of the jaws.

- The height of the can be adjusted by using any one of the following:

(a) A wooden packing under the base.

(b) A properly designed vice fixture.

(c) A wooden platform.

(a) Simple Bench Vice

ba It is made up of carbon steel. This bench vice is normally used for general purposes or is able to do most of the work.

(b) Swivel Base Bench Vice

This is mostly used in the tool room. The base is fixed with a bench by nuts and bolts, and its jaw is open in parallel and can be rotated at any angle from 0ο to 360ο.

(c) Quick Release Bench Vice

It is to an ordinary bench vice. The spindle and nut have buttress threads. Its movable jaw is open by using a trigger lever. If the trigger is pressed, then met disengages the screw- and the movable jaw can be set in any desired place quickly. It is mostly used in mass production workshops.

(d) Combination Bench Vice

It has a V-shaped jaw structure and is made up of cast steel that is fixed below the main jaw. Therefore, it is used to easily grip round-shaped jobs.

(ii) Machine Vice

It is commonly used in fitting shops for holding a variety of jobs such as sharping, milling, drilling, and grinding. It is made up of grey cast iron. Its fixed jaw is machined at 90ο and the movable jaw moves backward and forward in direction on the body through a spindle. It is widely used in machine shops.

(a) Simple Machine Vice

It is used for both light and heavy work. It has the tightened grip of the jaws with the workpiece. Its movable jaws hold the job in tightly.

(b) Swivel Machine Vice

This can rotate at any angle (0ο to 360ο ) on its base. Its base is divided into two parts. The bottom part is fixed with the table by nuts and bolts and its upper parts are fixed by clamp. So, it is easy to rotate in any Hardened direction.

This is mostly used to hold the job during milling, and drilling. machining, etc. Its size is mostly measured by the jaws.

(c) Universal Machine Vice

It is used in the tool and die maker section. Its jaw is open in parallel after fixing a job vertically or horizontally, parallel to the base. It can be rotated at any angle as shown in the figure. It is set perpendicular-wise at any angle. not used for heavy work because its rigidity is very low.

(d) Vertical Machine Vice

If a simple change in opposite directions, then its jaw is not horizontal, but it will become vertical direction so that, if we want to clamp on the table, then its base will be changed as shown in the figure. This vice is used for milling processes.

(e) Drill Machine Vice

It is used for plumbing and locksmith work in the drill machine. The jaws of a V-shape grip the pipe and cylindrical bars firmly for operations such as cutting, threading, etc.

(iii) Pipe Vice

It is used for clamping round sections and pipes, especially for plumbing and locksmith work. It has V-shaped jaws with teeth. It is used to hold round jobs and cylindrical workpieces. The jaw is moved up and down direction with equal pressure on the job from all sides so that, the pipe does not move or press. It is made up of cast iron and its spindle is made of mild steel.

(iv) Leg Vice

It is made up of forged steel. It is used in a smithy shop and can withstand the blows. It is most suitable for heavy hammering, chipping, and cutting in a fitter shop. A flat spring is fitted below both jaws and has a function to push the movable jaw. the spindle has square-cut threads and the handle is longer than the bench vice. So, it is used for hammering work.

(v) Hand Vice

It is used for holding keys, small drills, screws, rivets, and other similar objects, which are very small and can be easily held. It is used by hand with a job or workpiece, This is made in various shapes and sizes. It consists of two legs which are made up of mild steel.

The length of 125 to 150 mm and the width of the jaw varies from 40 to 44 mm. The jaws can be opened and closed by using the wing nut that is fastened to one leg and passes through the other.

(vi) Pin Vice

It is used for holding round jobs of very thin diameter such as wire and pins. It also forms a very useful handle for small files. It consists of a handle and a tapered nose, covering a small collet chuck at its end.

The chuck carries the jaws, which are operated by turning the handle. It is commonly used by a watchmaker and in the instrument section.

(vii) Tool Maker’s Vice

It has a clamping screw with the movable jaw of the vice. It exerts download force that keeps the workpiece from lifting out of proper alignment. This is made up of high-grade alloy steel. All surfaces are titanium nitride coated for additional wear and corrosion resistance.

It is used for holding small intricate workpieces for filing and machining and this can be set at any angle.

(viii) Carpenters Bench Vice

This is used in carpentry shops for wooden work. Its body is made up of cast iron and its jaw is made up of hard woods. This is similar to working a quick-release and its spindle is attached to the handle to move the jaws. So, the handle is helped to move the spindle. Its spindle has buttress threads.

(ix) C Clamp Vice

Its construction is such as the alphabet C. So, it is called a C clamp. It is made up of cast steel and used for round taper or zig-zag jobs.

The C-clamp has an adjustable screw with a spindle at one end. It is widely used in fabrication works and the buildup of two parts of a metal.

(x) Parallel Clamp Vice

This is also called a tool maker clamp and has two parallel jaws. These jaws are connected with a screw respectively. Its one edge is fixed and the second edge is pin-up with a screw and used for providing the tension with the clamp. These clamps are ready to grip the workpiece. The parallel clamp is used for finishing the job for drilling, soldering, breezing, etc.

Precautions While Using Vice

Precautions using

(i) It must be cleaned before the job is gripped with jaws.

(ii) Lubricants should be dropped into the spindle regularly for a short fixed period, in all shades and parts.

(iii) The job should be gripped at the center of the jaw.

(iv) He should be tightened with a hand, not by the hammer.

(v) Never use hammering.

(vi) Always use a soft metal clamp for finishing the job.

(vii) He should not be loose.